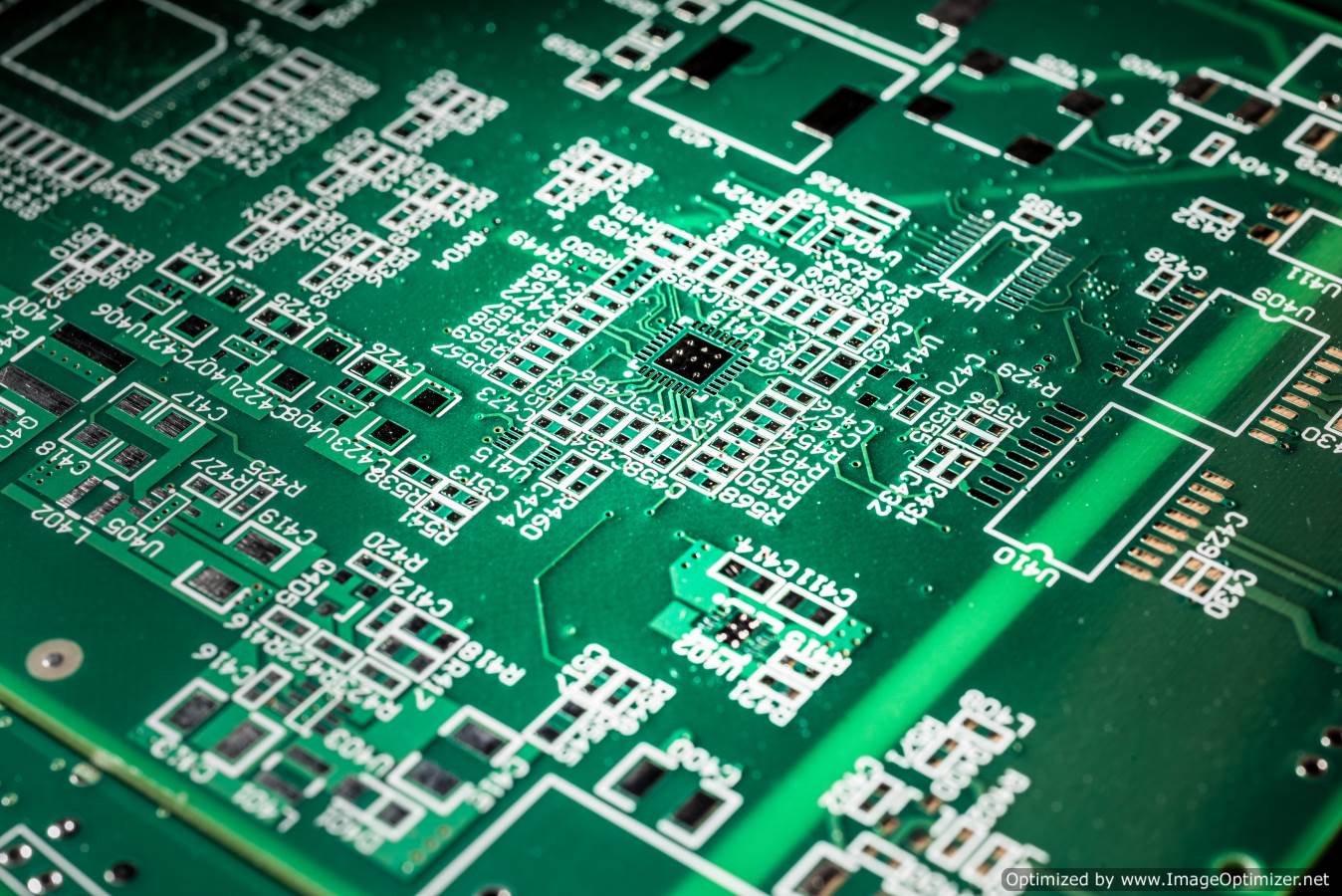

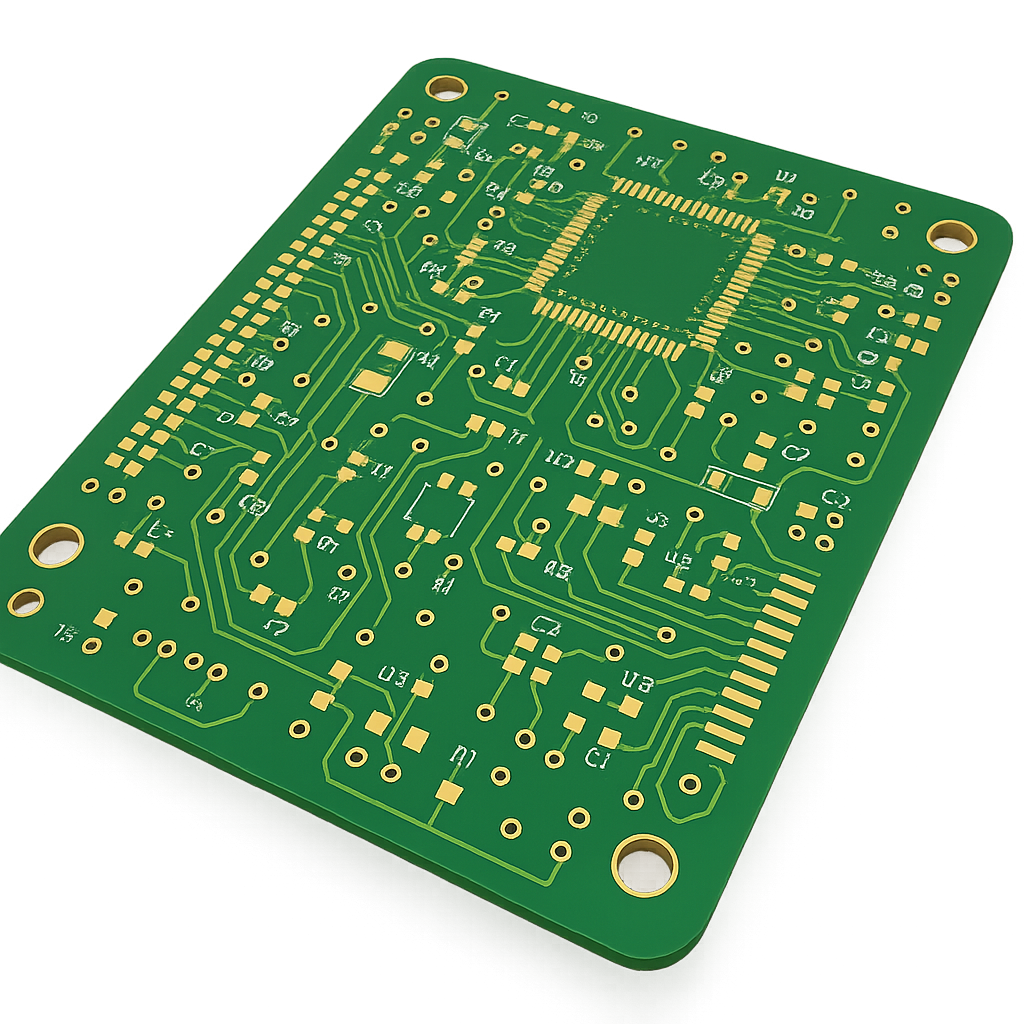

Present-day printed circuit boards contain a plethora of critical components, yet nothing is more vital for efficiency than the surface itself. The surface of modern PCBs performs two main functions: providing a solderable surface to strongly attach electrical components to and protecting exposed copper circuity by using the right finish.

Within the PCB assembly and manufacturing process, a surface finish is the ultimate key to enhancing the durability and longevity of a completed circuit board. This vital coating lies between a component and the bare board. Let’s examine closer the most standard finishes for PCB assemblies. Here are five different types of printed circuit board surface finishes to keep in mind for your project.

Hot Air Solder Leveling: HASL

HASL is a common surface finishing option—the tried-and-true method for a wide array of PCB projects. This is because HASL is a finish type that’s widely available and economical for long-term use. HASL works well for through-hole component boards as well as circuit boards with larger SMT components. Essentially, the protective coating forms after submersion into molten solder and leveling with a hot air knife. This well-known finish is not ideal for fine-pitch, sensitive handling, or smaller intricate surface mount component due to leveling inconsistencies. If lead is a material concern, lead-free HASL is also an alternative with an excellent shelf-life that meets RoHS regulations.

Immersion Silver or Immersion Tin

Immersion coatings are far better options for board surfaces containing smaller components. IAg is a non-electrolytic silver immersion finish that forms via a chemical process. The silver surface layers typically diffuse the copper layer through an immersion reaction. Stable and suitable for fine pitch, this reliable method also provides quick signal speed. It is important to keep storage conditions in mind, as silver tends to tarnish through air exposure.

On the other hand, immersion tin is a cost-effective alternative finish that is RoHS compliant. Similarly, the flat coating is ideal for smaller components, fine pitch, and faster circuitry speeds. However, if your production volume isn’t high, you may desire to stick with immersion silver to avoid ISN’s drawbacks.

Organic Solderability Preservative: OSP

OSP is a simple coating process that works wonderfully to ensure flat surfaces. The thin water-based finish consists of organic carbon compounds that protect the copper for sturdy soldering. While OSP eliminates the need for metal surface finishes, the RoHS-compliant material is not as commonly used today.

Electroless Nickle Immersion Gold: ENIG

ENIG is the most utilized lead-free coating of these five different types of printed circuit board surface finishes. ENIG is a two-layer metallic surface coating—nickel as the main barrier layer for soldering—and gold as a thin protective layer over the nickel. Since the plating is incredibly durable and sturdy, users can expect a longer shelf life. However, the more complex process does raise finishing costs.

Uncertain of what surface finish you will need for your PCBA project? Consult with a professional for a cost-effective design that ensures optimal performance. You can turn to Advanced Assembly for quick-and-easy printed circuit board turnkey services. The highest-quality results await—contact us for a quote today.