Extensive rigid-flex expertise

Types of flex circuits

-

Single-Sided Flexible Circuits

- Single copper conductor layer on a flexible dielectric film.

- Double-sided copper clad material with top and bottom cover films. The two conductive layers have an insulating layer between.

- A combination of single and/or double-sided flex circuits laminated with adhesive onto a single and/or double-sided material.

- Used to accommodate the entire conductor pattern of electric circuit within one component.

Double-Sided Flexible Circuits

Multi-Layer Flexible Circuit Boards

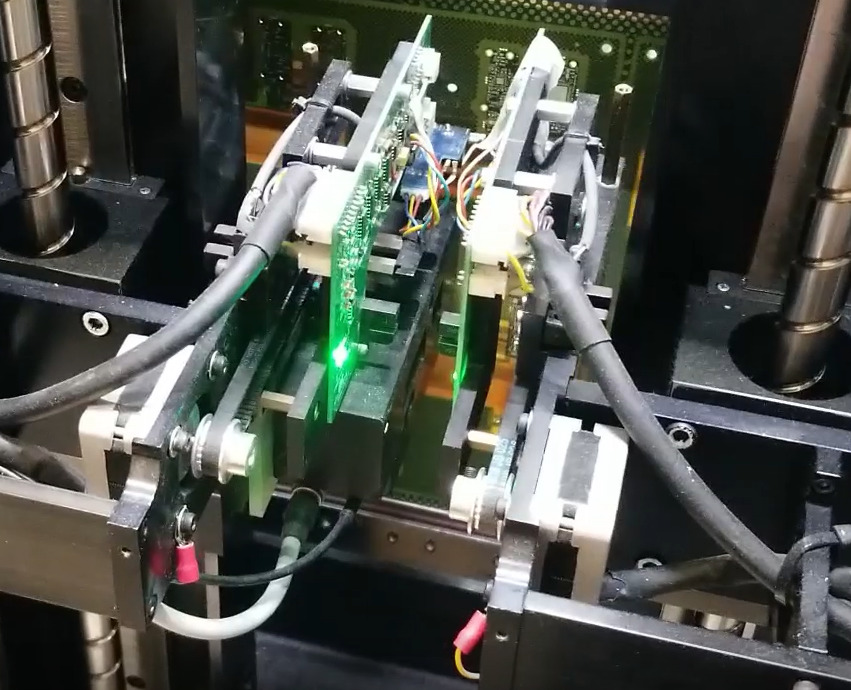

Rigid Flex Circuits

Rigid-flex and flex capability highlights

- High-layer count

- Adhesive and adhesiveless

- Book binder

- Stiffeners

- Laser skiving

- Laser-drilled microvias

- Epoxy fill

- Heavy copper

- Extra-long flex “cables”

- Turnkey assembly

- View all capabilities

We manufacture a broad range of PCB types and technologies for a one-stop solution

Contact us

We’re available to answer any questions.

Email Us

info@summitinterconnect.comCall Us

(877) 264-0343Send us an email

— Fill out the form below and send the message.