Excessive heat can damage components, reduce signal integrity, and shorten product lifespan. Effective thermal management ensures stable performance, reliability, and long-term durability.

Advanced Thermal Management PCB Solutions

Effective heat management is essential to prevent component failure, ensure signal integrity, and extend product life. Summit delivers advanced materials and design techniques that keep boards cool and reliable.

Heat Dissipation Solutions

Managing heat is critical to PCB performance, reliability, and product lifespan. Excessive temperatures can degrade components, weaken solder joints, and compromise signal integrity. Effective thermal management uses conductive materials, vias, copper planes, and heat-sinking strategies to spread and remove heat efficiently.

Summit offers advanced thermal solutions engineered to keep designs running cooler and more reliably.

Essential Thermal PCB Features

- Materials with high thermal conductivity improve heat flow.

- Copper planes and heavier copper spread heat evenly.

- Thermal vias transfer heat away from hot components.

- Embedded coins deliver targeted, localized heat sinking.

- Integrated heat sinks enhance dissipation and stability.

Designing for Thermal Reliability

Managing heat starts with smart design choices. Material selection, stack-up configuration, via structures, and heat-spreading features all influence how effectively a PCB performs under thermal stress.

By combining advanced analysis with practical fabrication experience, Summit helps customers implement effective heat dissipation strategies.

Design Support Highlights

- Guidance on material selection for conductivity and reliability.

- Stack-up optimization to balance thermal and electrical needs.

- Via design recommendations for effective heat transfer.

- Expertise in copper coin and heat sink integration.

- Early DFM collaboration to reduce rework and risk.

Thermal Management capabilities highlights

-

High-Conductivity Dielectric Materials

Improve heat transfer through the PCB structure. Summit's expertise with advanced laminates ensures the right material is matched to performance needs.

-

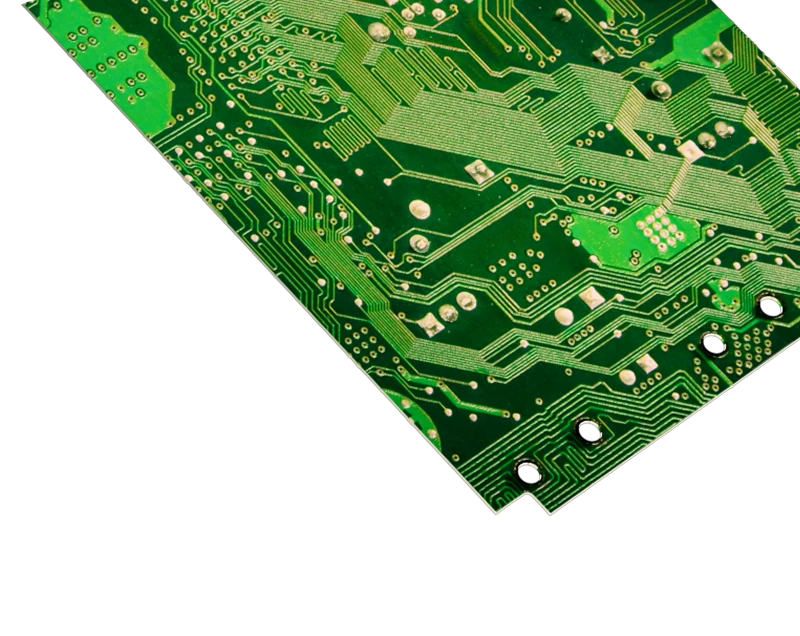

Heavy Copper and Copper Planes

Spread heat evenly and increase current capacity. Our proven processing of thick copper and plane layers delivers reliable thermal and electrical performance.

-

Thermal Vias

Move heat away from hot components efficiently. Our technologies maximize conductivity and reliability to optimize via design, plating, and fill.

-

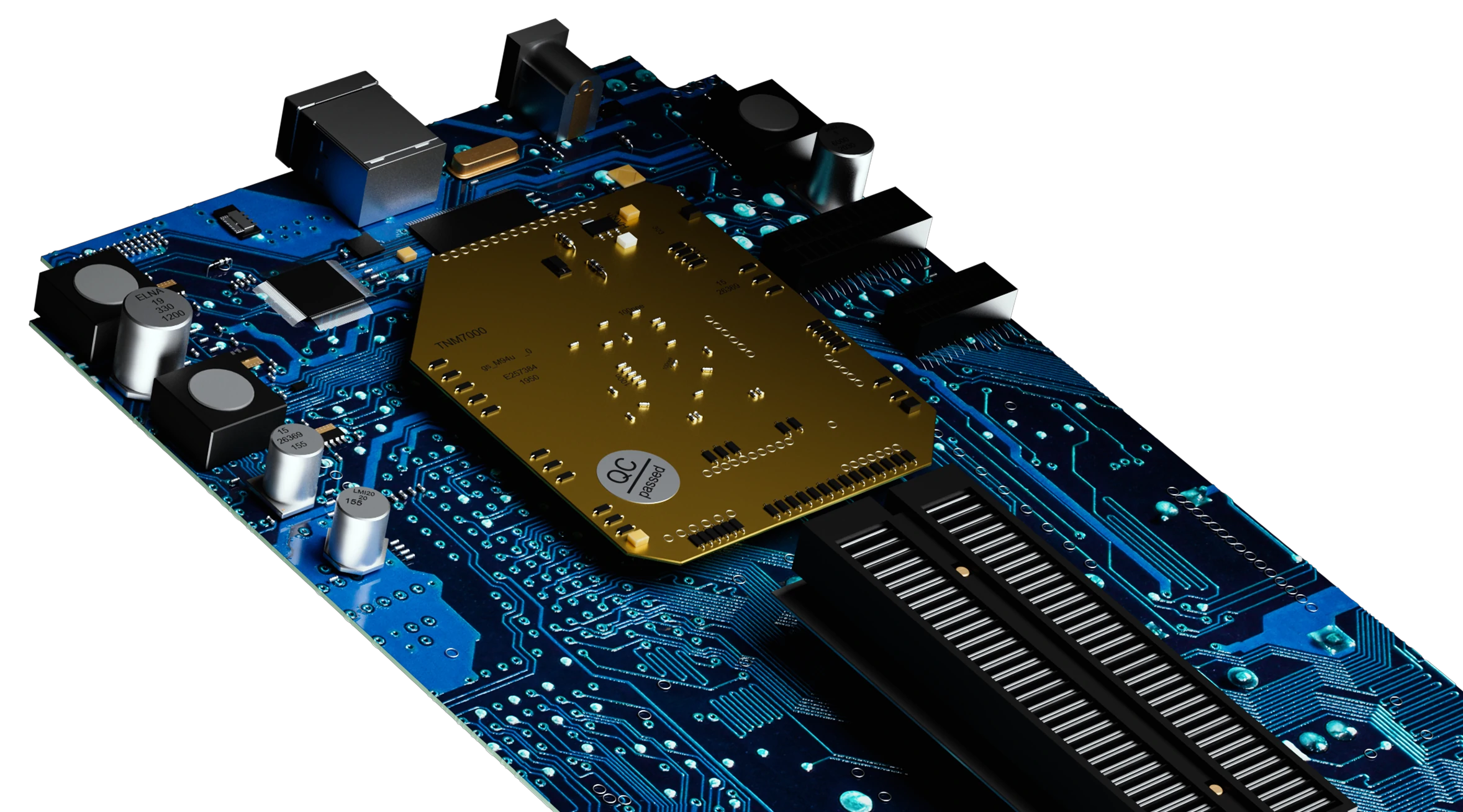

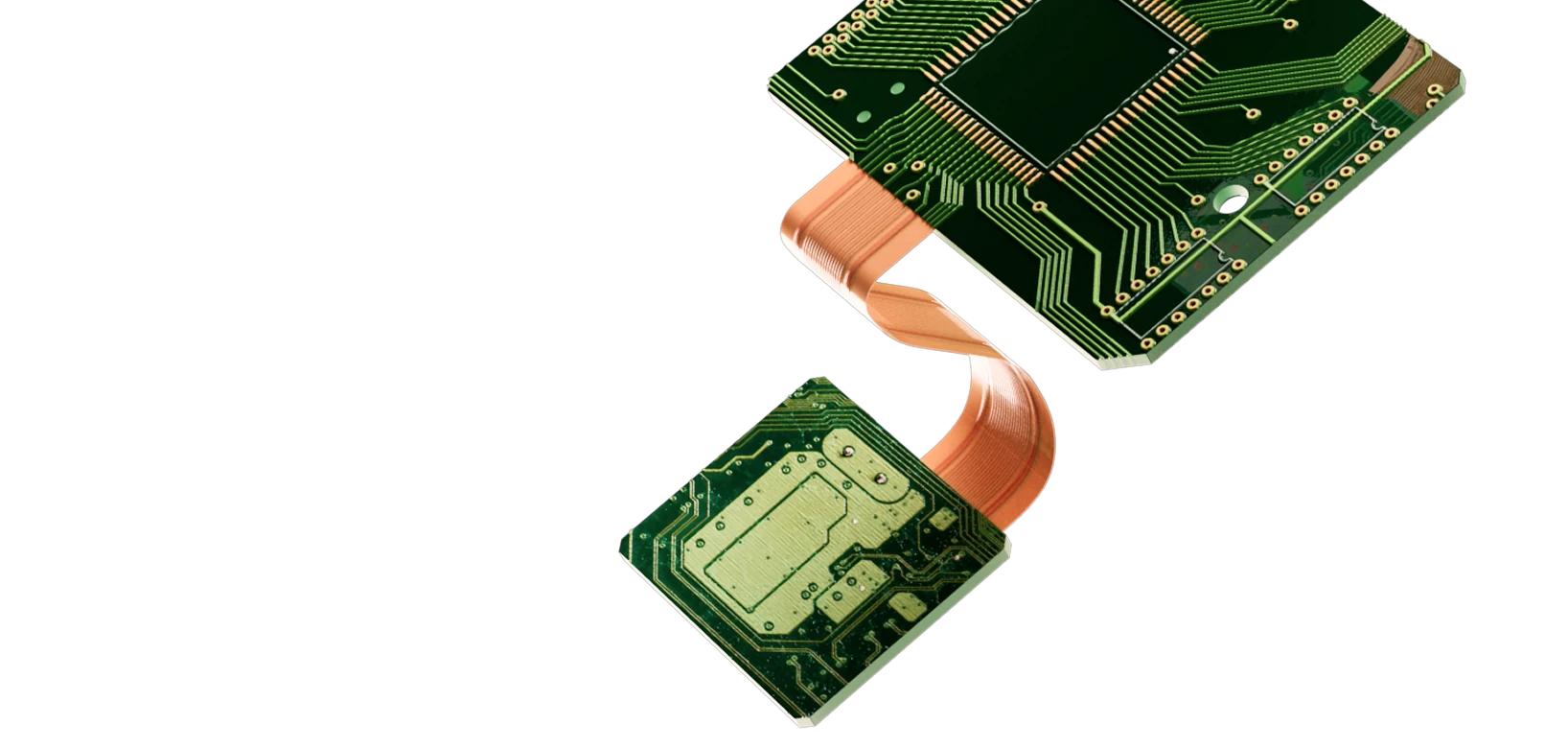

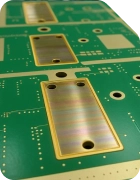

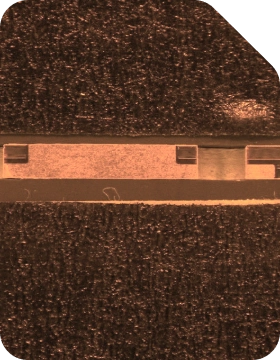

Copper Coin Technology

Provide localized heat sinking at critical components. At Summit, embedded or bonded copper coins are engineered with precision for effective thermal transfer.

-

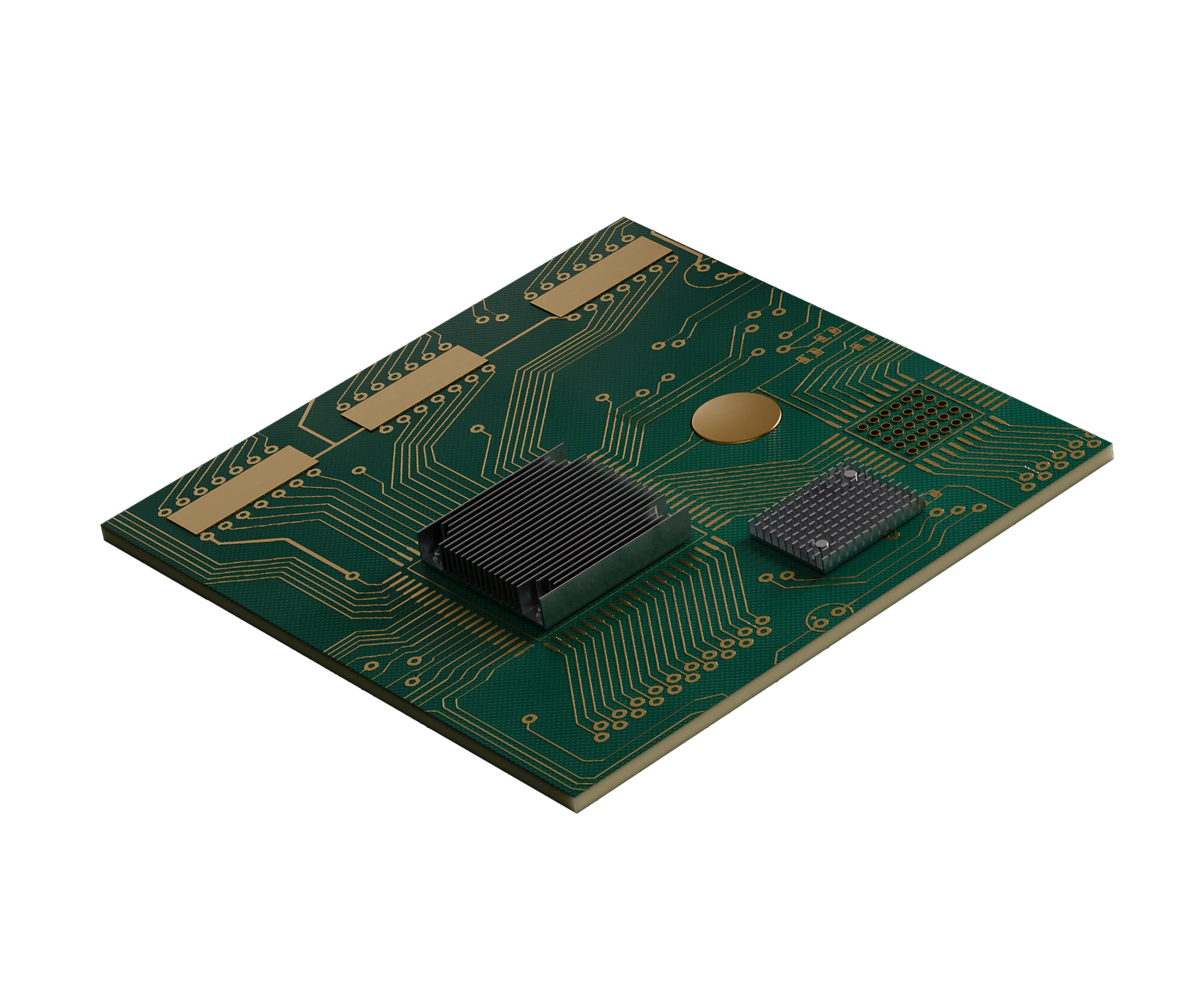

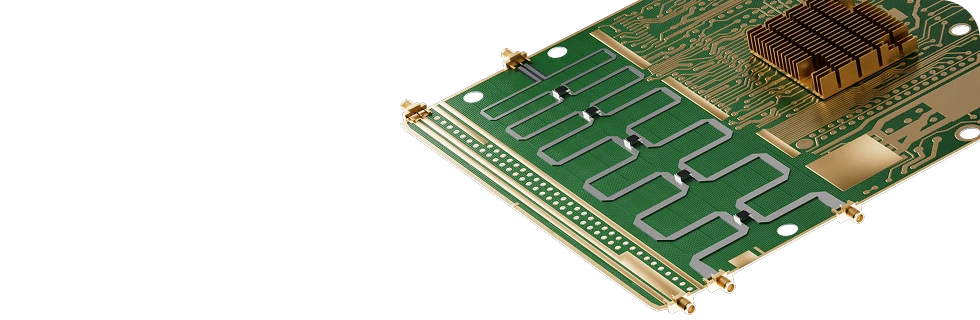

Integrated Heat Sink Solutions

Enhance dissipation in high-power applications. Summit's expertise in bonded aluminum and copper sinks ensures secure attachment and thermal performance.

-

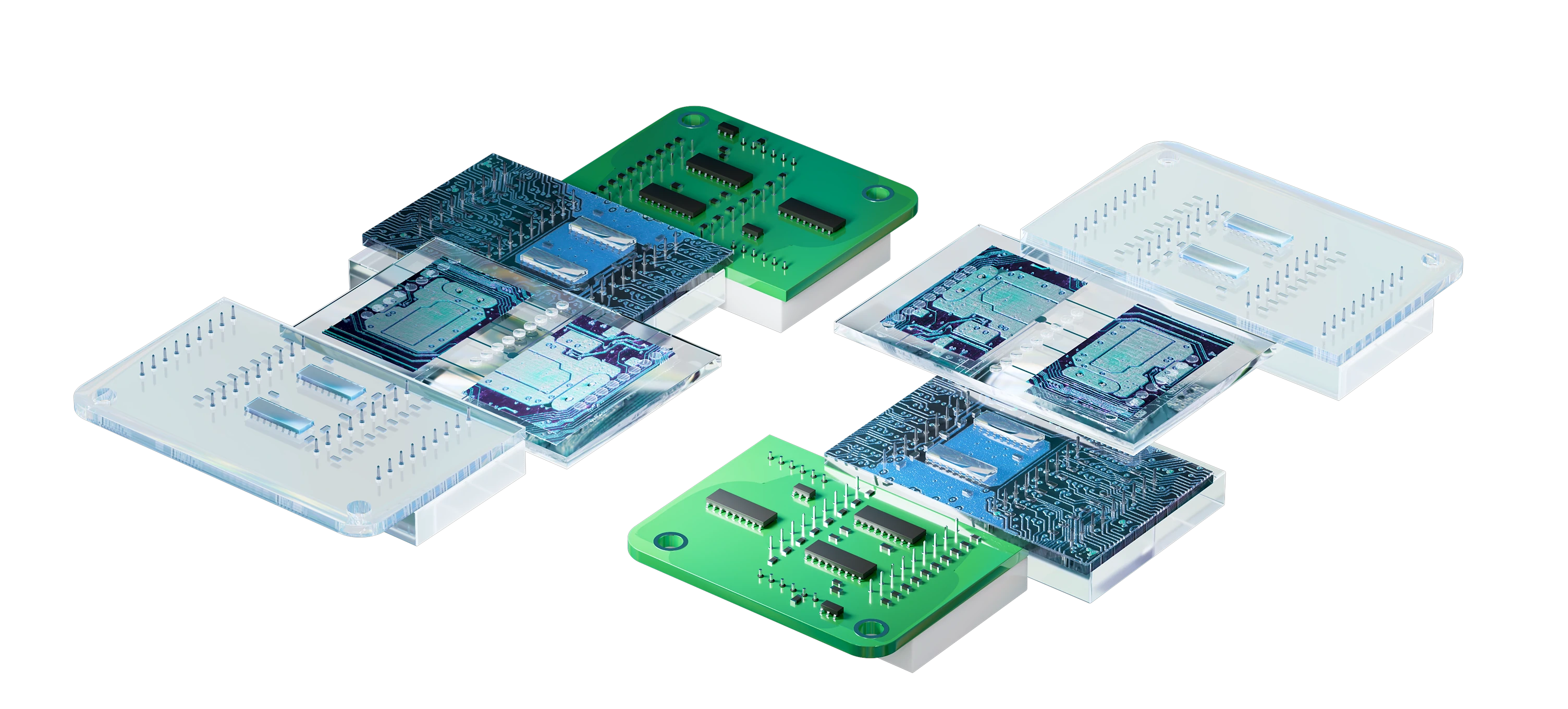

Controlled Depth Milling

Create cavities for coins, sinks, or embedded cooling. Our precision milling capability enables accurate thermal features without compromising board integrity.

Embedded Heat Sink Strategies Reference Guide.

Learn how to embedded heat sinks into a PCB cavity to extract thermal energy from high-power components

We’re available to answer any questions

-

Email Us

info@summitinterconnect.com -

Call Us

+1 (877) 264-0343

Frequently asked questions.

-

-

High-conductivity dielectrics such as PTFE, ceramic-filled laminates, and specialized resin systems outperform standard FR-4 by conducting heat away from critical components.

-

Thermal vias transfer heat vertically through the board into copper planes or heat sinks, significantly lowering component temperatures and spreading heat more evenly.

-

Copper coins are embedded or bonded inserts that act as localized heat sinks under hot components, providing highly efficient thermal transfer without increasing board thickness.

-

Summit partners with engineers early in design, recommending materials, via structures, and heat-sinking strategies to ensure manufacturable, reliable, and cost-effective thermal solutions.

We manufacture a broad range of PCB types and technologies for a one-stop solution

-

Prototype Assembly

Looking to test your design before committing to a full PCB production run? Small-quantity prototype PCBs are manufactured with the same state-of-the-art equipment and quality processes used for production runs.

-

RF / Microwave

We specialize in semiconductor reference cards, probe cards, DUT, and burn-in-boards. Our RF capabilities include high aspect ratio, low-loss materials, bondable gold, tight tolerance drilling, and sintering.

-

High-Density Rigid

Summit provides HDI rigid PCBs with microvias, blindburiedvias, back drilling, via fill, metal core, and large panel options.

-

Rigid-Flex and Flex

As experts in rigid-flex and flex manufacturing, we handle rigid-flex, bookbinder, multilayer, adhesiveless & adhesive, stiffeners, laser ablation, thin flex laminates, assembly options and more.

Additional PCB resources

-

Dec 16, 2025

How Embedded Heat Sinks Are Advancing PCB Fabrication

-

Dec 16, 2025

Thermal Expansion Considerations

-

Dec 16, 2025

Selecting the Best PCB Material for High-Speed Applications

-

Dec 16, 2025

10 Causes of Lamination Voids and Ways Designers Can Prevent Them

-

Dec 16, 2025

RF & Microwave PCB Design: Navigating High-Frequency Complexity with Precision

-

Dec 16, 2025

How to Thoughtfully Design Embedded Cavities into a PCB

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing