Over a century ago, complex wiring brought electronic devices to life. Now, these wires are replaced with printed circuit boards, or PCBs. The job of a PCB is twofold: to connect all the electronic components within a device, and to insulate these fragile components when connected to a power source.

With so many different industries and devices utilizing PCBs, the construction of these critical components has evolved. There are now six different types of printed circuit boards, including:

- Single-sided

- Double-sided

- Multilayer

- Rigid

- Flex

- Rigid-flex

We will explore each of the six types of printed circuit boards and their applications below.

Single-Sided PCBs

Single-sided PCBs are the most popular choice of electronic manufacturers. These affordable and easy-to-build boards are made from a substrate, which is the material that holds all the board’s components. One conductive copper layer is added above the substrate. On one side of the PCB are the electrical components, and the entire circuit is viewable on the other. Because of their simple nature, single-sided PCBs are used in basic applications like calculators, electronic toys, and timing circuits.

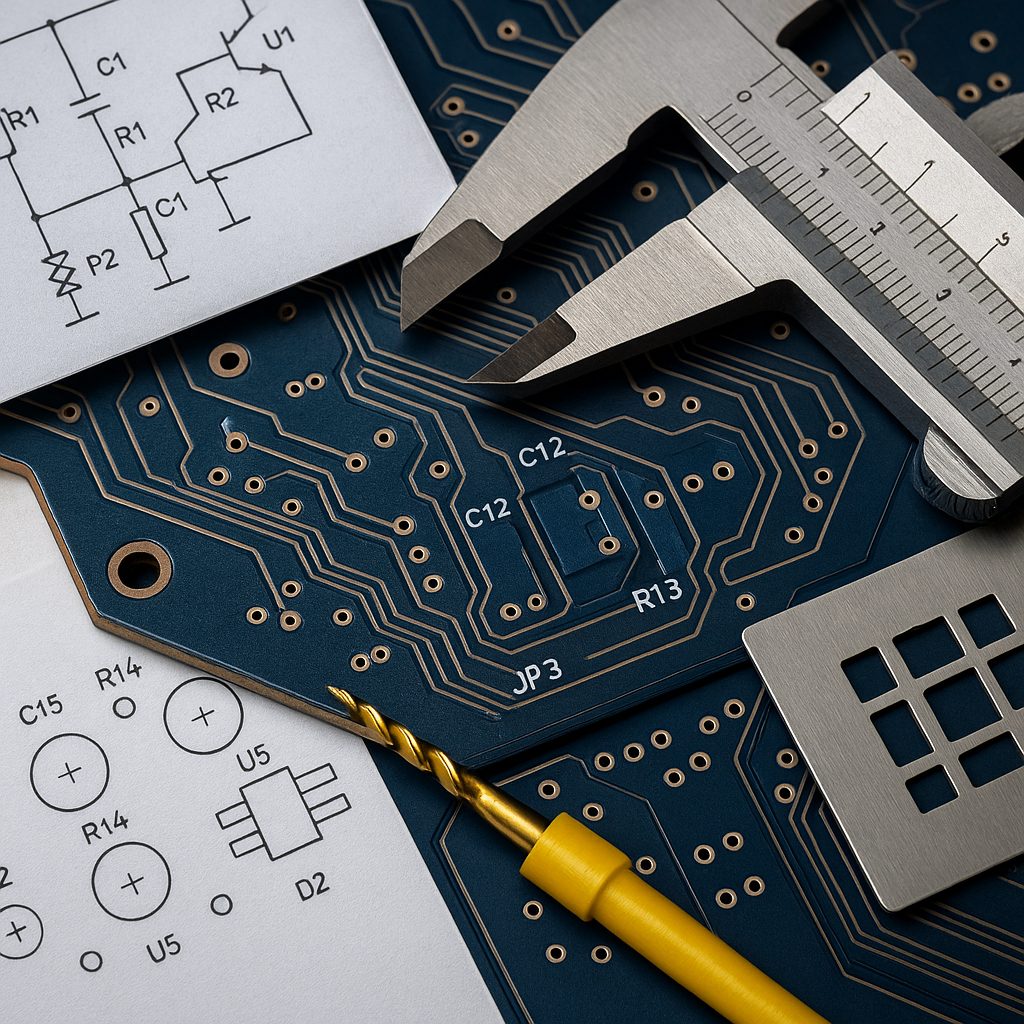

Double-Sided PCBs

Double-sided PCBs feature two conductive layers, one on the top and one on the bottom of the board. Holes are drilled in the PCB to allow metal components to connect the circuits on either side. These slightly more complex boards are used in cell phones and amplifiers.

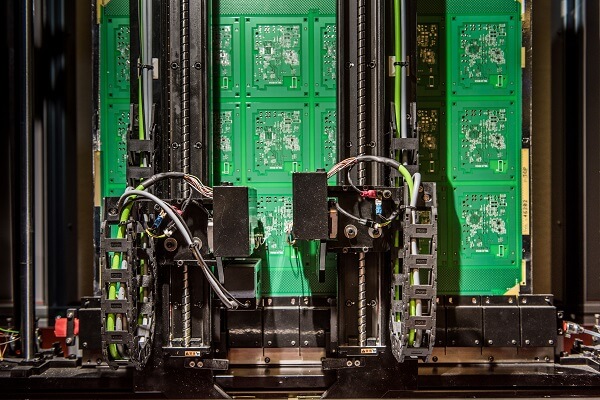

Multi-Layer PCBs

Featuring at least three conductive layers, multi-layer PCBs are ideal for more complex electronic devices. Each conductive layer is sandwiched between insulating sheets and are bonded and laminated together. These PCBs tend to be on the smaller side but pack a powerful punch. Multi-layer boards are often used in computers, tablets, and medical equipment.

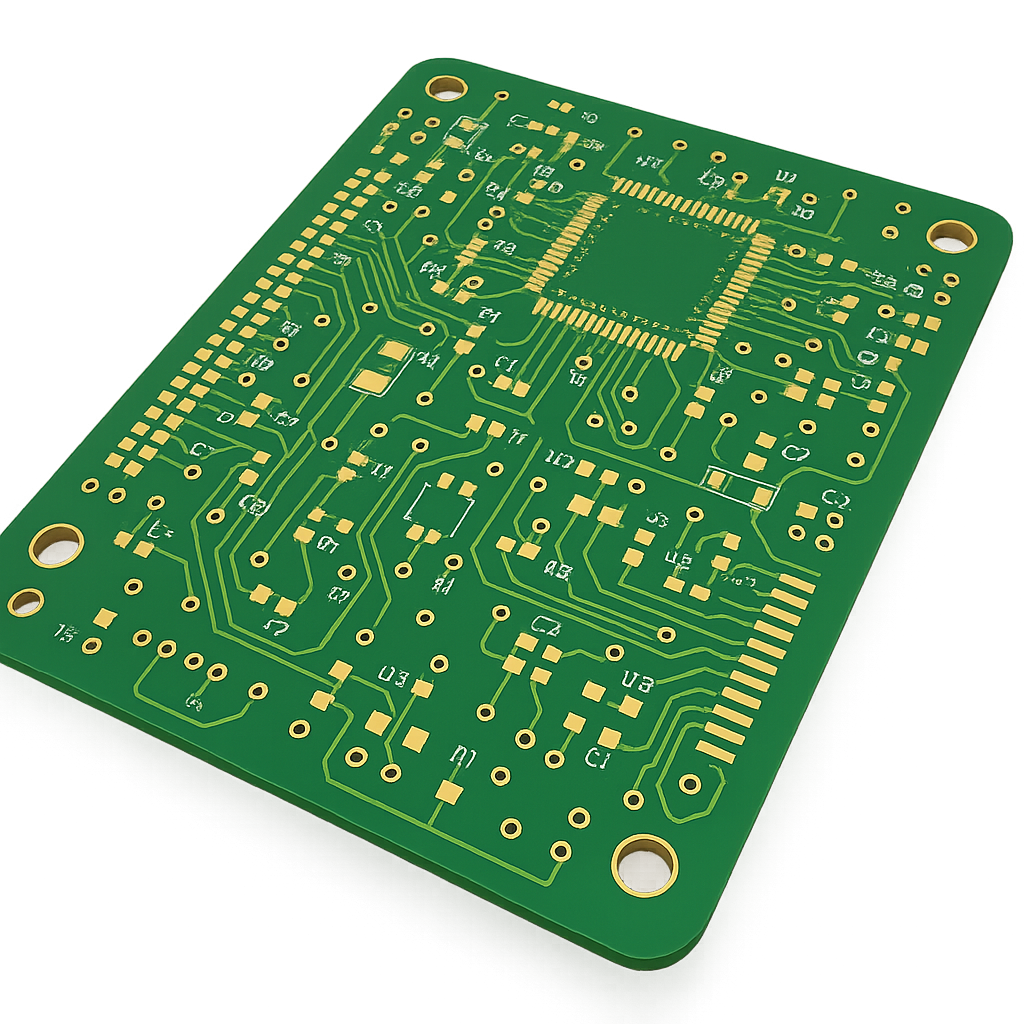

Rigid PCBs

Rigid PCBs feature an inflexible substrate and cannot be twisted, bent, or folded. Oftentimes these lightweight and cost-effective boards are made with numerous layers, including a substrate, conductive, solder mask, and silk screen layer. Rigid PCBs can be single or double sided, or multi-layered. They are typically used in X-ray machines, MRI systems, and GPS equipment.

Flex PCBs

Flexible printed circuit boards are a rising favorite due to their ability to be bent, twisted, or folded to fit their electronic device. Rather than placing printed circuits and electronic components on a rigid substrate, these elements are placed on a flexible one – mostly a conductive polyester film. Flex PCBs can be single- or double-sided as well as multi-layered. These boards are often used in automotive applications, medical devices, and cameras.

Rigid-Flex PCBs

These hybrid PCBs feature the best of both worlds. Flexible yet rigid, these circuit boards are designed and built in 3D. This enables them to be tailor-made for the device in which they’ll be used. Rigid-flex PCBs are also lighter in nature as they don’t require connectors. These complex PCBs are utilized in critical applications such as aerospace and medical devices.

To inquire about a single-sided, double-sided, multi-layer, rigid, flex, or rigid-flex PCB, reach out to our team at info@summitinterconnect.com.