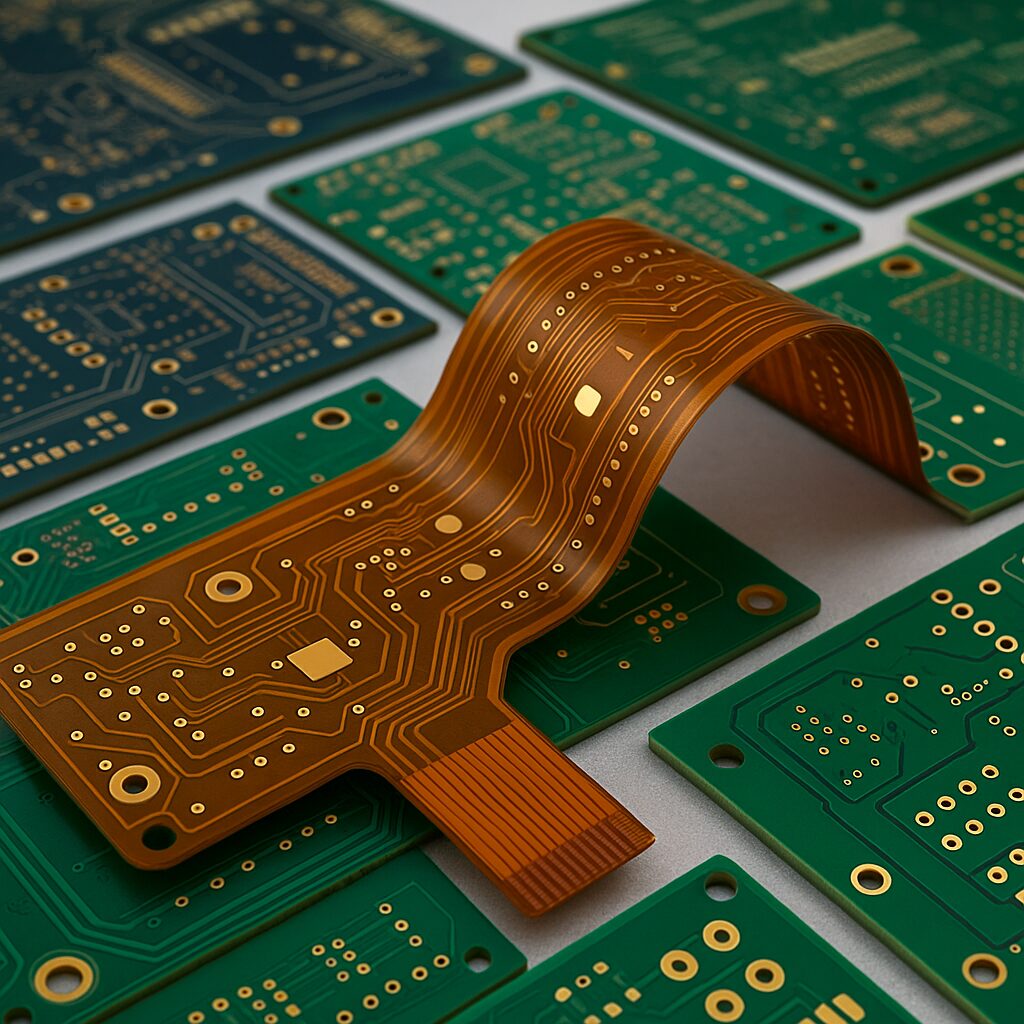

In the intricate world of PCB design and fabrication, every detail counts. One such detail that often requires careful consideration is the tolerance of holes drilled into the board. But how should one express these tolerances on a drill table to ensure standard practices are followed? We recently received this question from one of our customers and would like to publish this educational content to assist others facing similar queries in the PCB design and fabrication community.

Question: How should I express hole tolerance on a drill table if I want standard tolerance?

Answer: The typical finished hole sizes in a PCB are expressed as finished holes unless otherwise specified. The typical tolerance for plated component holes have a tolerance of +/-0.003”, and press fit connectors may have a tolerance of +/-0.002”. Vias should be specified with a tolerance of +0.002/- Nominal Hole Size. This allows the fabricator to select a drill diameter that will produce the highest yield with the greatest opportunity to meet the specified annular ring requirement. Non-plated hole size should allow for a tolerance of +/-0.003” but may be reduced to +/-0.002”.

If you have any questions related to engineering or manufacturing that you would like answered, please feel free to email our expert team for assistance.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing