RF / Microwave

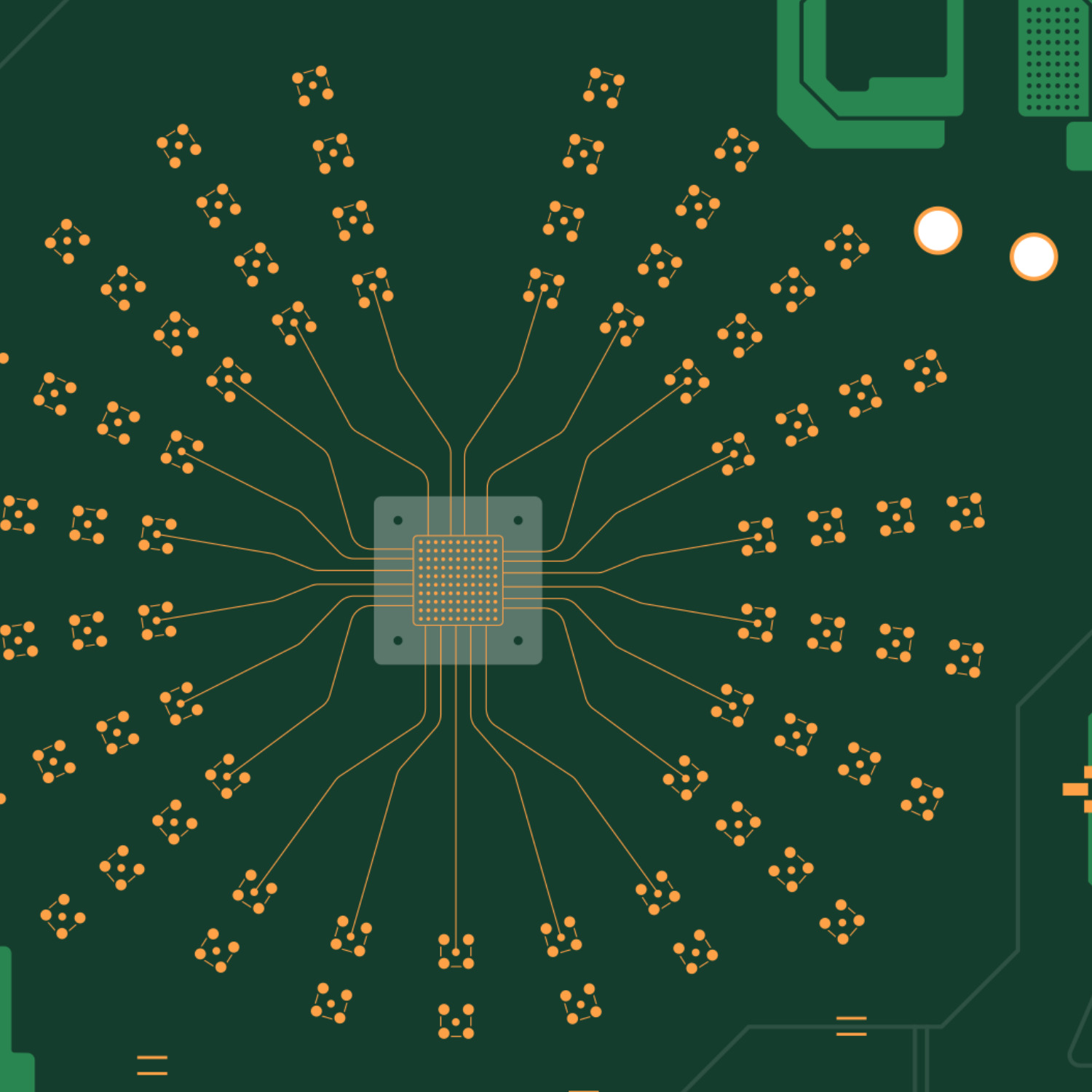

RF circuits have moved from large

mil-aero applications into a rapidly growing range of commercial products. Smaller boards with RF/microwave circuits on board are substantially more complex, requiring a PCB manufacturer with Summit’s expertise.

Design complexity

High-speed characteristics

RF/microwave signals are highly sensitive to the impact of noise, crosstalk, and power.

There are many considerations when integrating RF onto PCBs, including tight-component densities, multiple surface finish possibilities, board thickness considerations, wide ranges of reliability requirements, and even substrate-material choices.

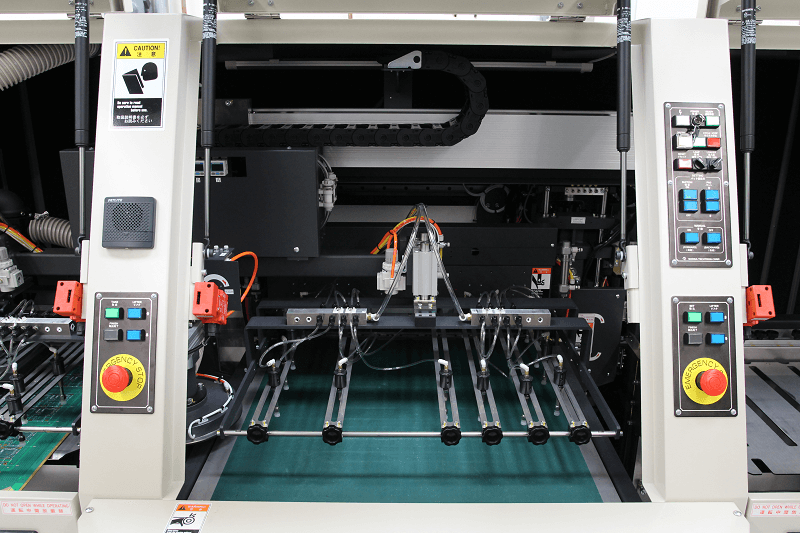

In addition, RF/microwave designs can require special manufacturing equipment. Fortunately, Summit has made significant investments in the equipment and field application engineering experience required for accurately manufacturing these PCBs.

Summit RF / microwave PCB capabilities

We manufacture a broad range of PCB types and technologies for a one-stop solution

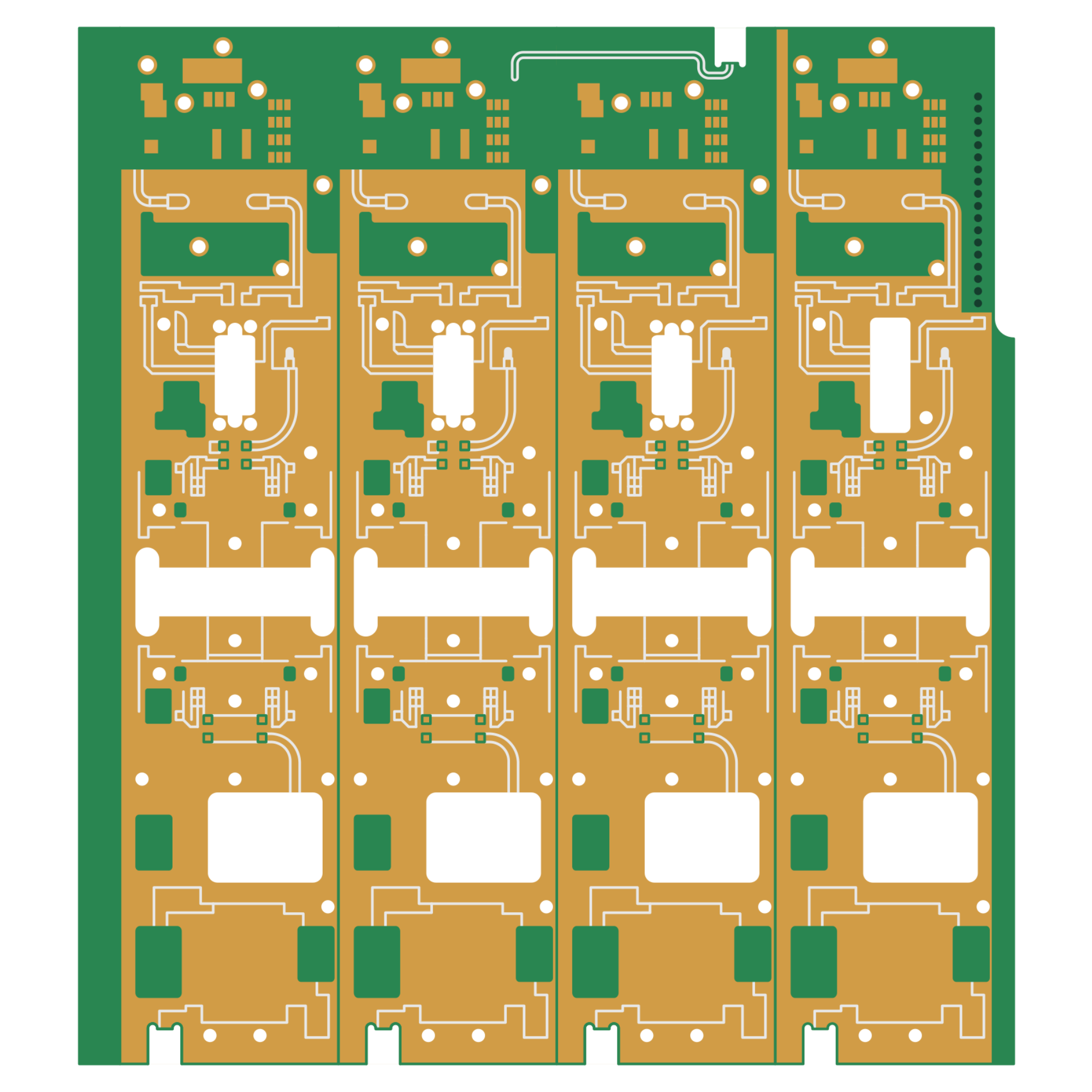

High-Density Rigid

Summit’s rigid capabilities include HDI high-layer count boards, staggered microvias, blind/buried vias, back drilling, multiple sequential lam, via fill, metal backed/metal core, and oversized panel options.

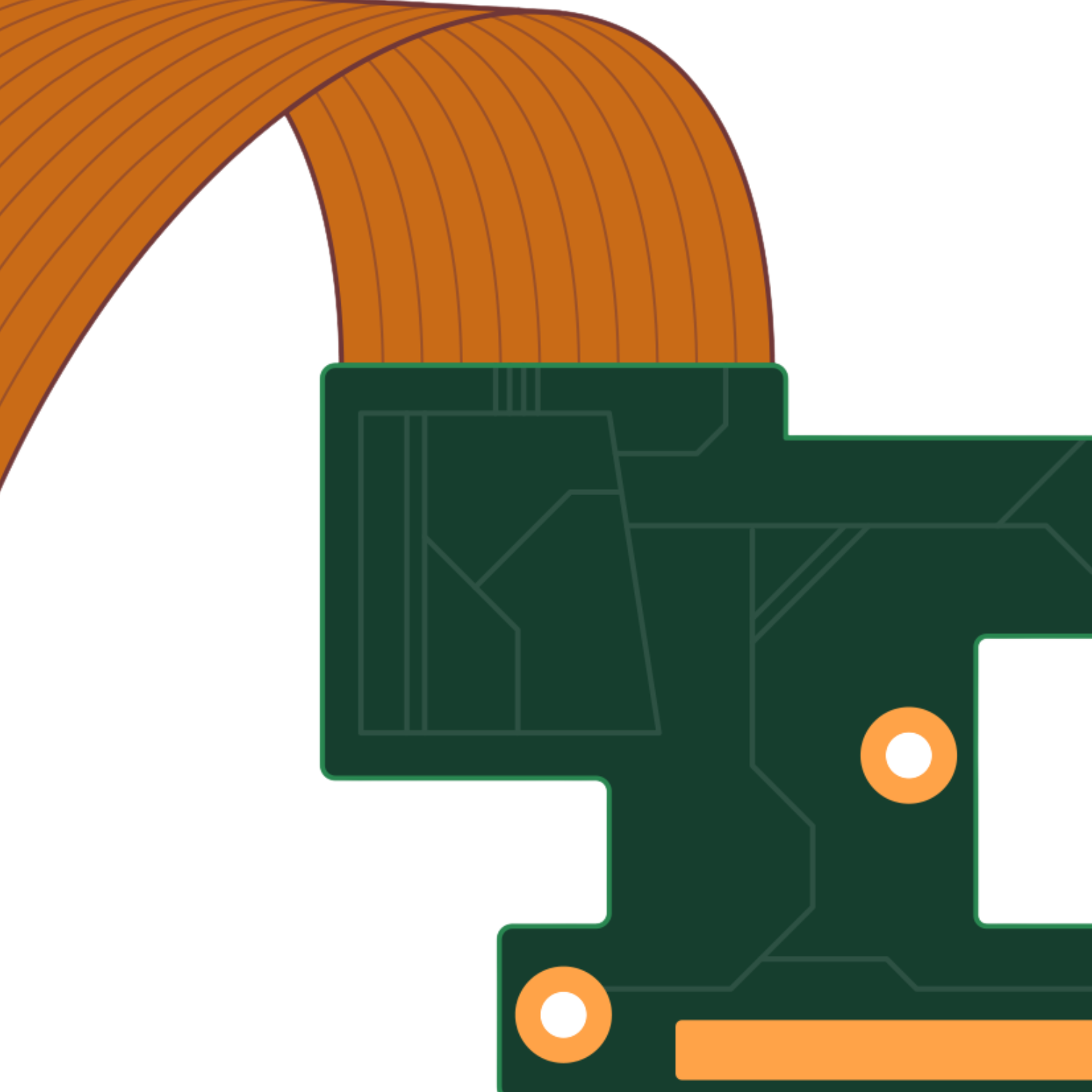

Rigid-Flex and Flex

As experts in rigid-flex and flex manufacturing, we handle rigid-flex, bookbinder, multilayer, adhesiveless & adhesive, stiffeners, laser ablation, thin flex laminates, assembly options and more.

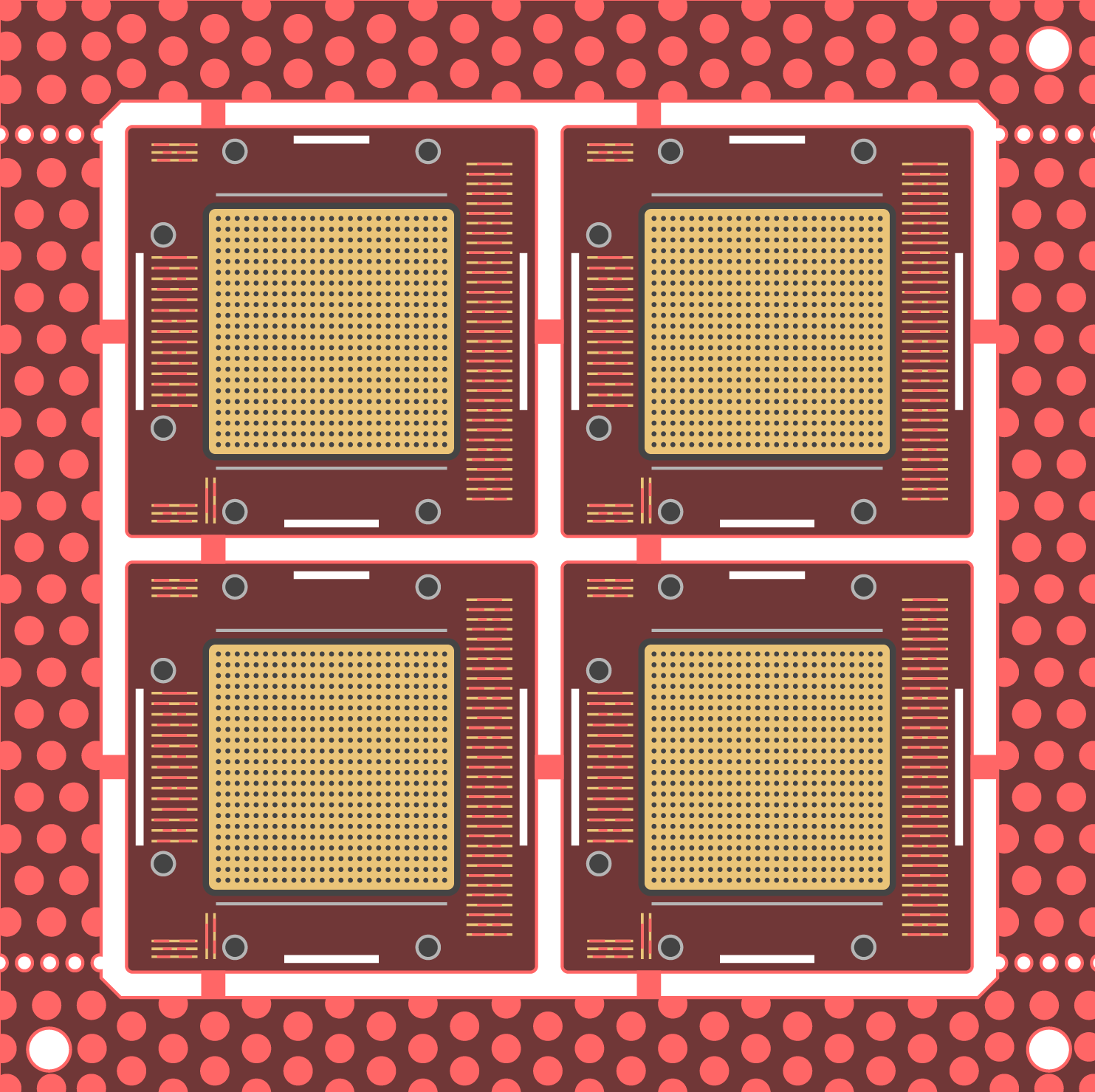

Semiconductor

We specialize in semiconductor reference cards, probe cards, DUT, and burn-in-boards. Our RF capabilities include high aspect ratio, low-loss materials, bondable gold, tight tolerance drilling, and sintering.

Additional RF resources

Contact us

We're available to answer any questions.

Email Us

info@summitinterconnect.comCall Us

(877) 264-0343Send us an email

— Fill out the form below and send the message.