Turnkey assembly means Summit manages the entire PCB production process—from sourcing components and manufacturing the bare boards to assembly, testing, and delivery. This streamlined approach reduces lead times, minimizes vendor management, and ensures consistent quality across all stages.

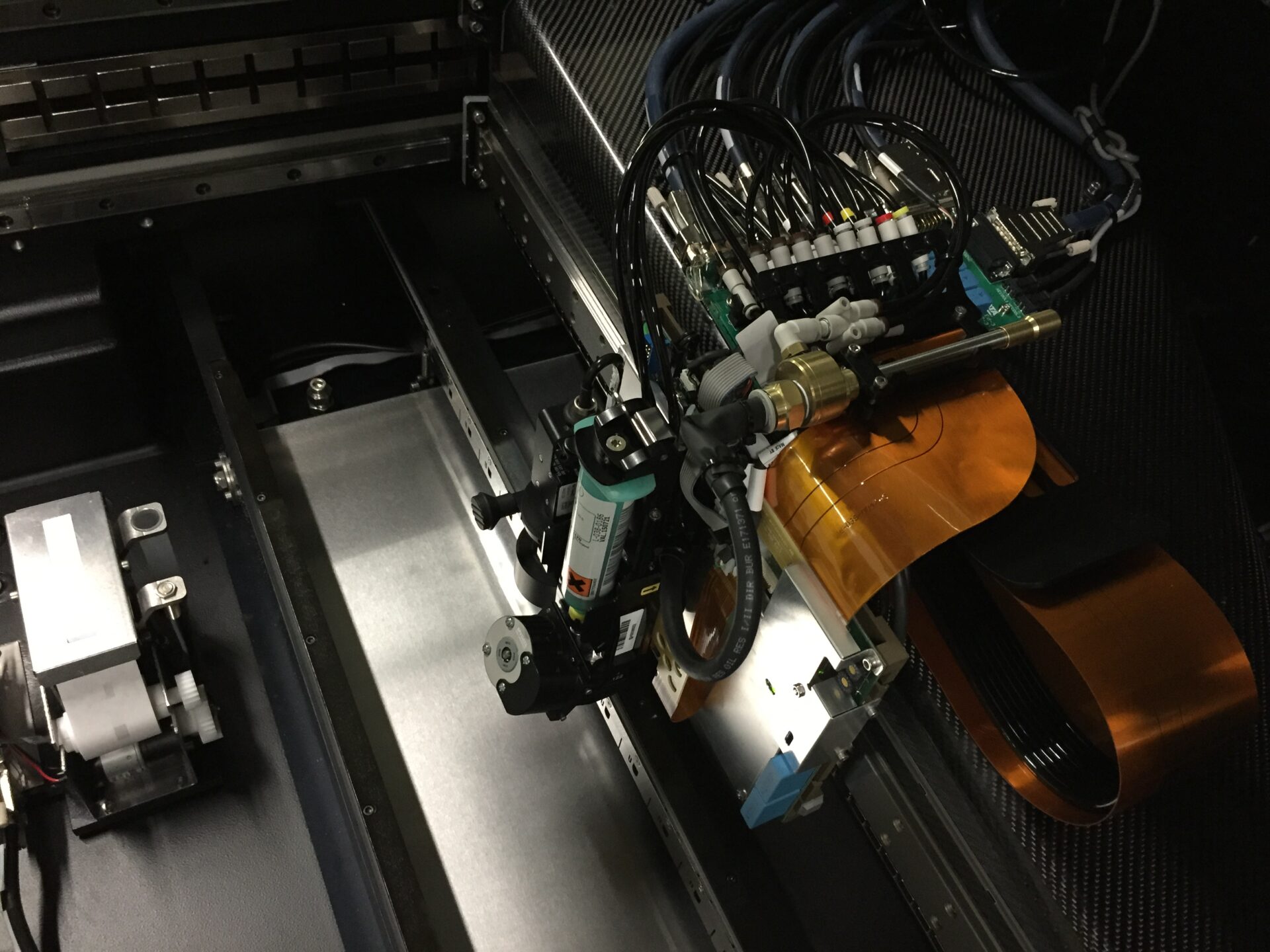

Quick-Turn Prototype Assembly

Summit makes assembling your circuit boards quick and easy. With more than 20 years of experience and over 50,000 unique PCB designs assembled, we provide flexible assembly services and personal support to ensure a seamless, hassle-free process that keeps your projects on schedule.

Full Turnkey PCB Assembly

Full turnkey PCB assembly streamlines your build for speed and simplicity by combining component procurement, PCB fabrication, and assembly into a single managed workflow. This approach eliminates coordination challenges between vendors, reduces production time, and ensures full traceability and quality control.

With one partner overseeing every stage, customers benefit from 3-4 day standard turns, consistent performance, and simplified project management from start to finish.

Why Choose Full Turnkey Assembly

- Single-source management saves time and resources.

- Consistent quality control across all stages.

- Faster lead times with coordinated production.

- Reduced procurement and logistics complexity.

- Seamless communication and accountability throughout the build.

Consignment and Partial Turnkey Assembly

Do you want to supply your own parts or boards? Our consignment services provide flexibility for customers who prefer to supply some or all components while leveraging Summit’s expertise in assembly and testing. This approach is ideal for customers with established vendor relationships or unique component requirements.

Important Considerations for Consignment Orders

- Components must be properly labeled and packaged.

- Include a complete bill of materials (BOM) with each order.

- Provide adequate overages to account for assembly attrition.

- Verify component quality and compatibility before shipping.

- Ship all parts together to avoid production delays.

Quick-Turn Prototype Assembly Capabilities

-

SMT and Thru-Hole Expertise

Full-service assembly for surface-mount and thru-hole components with precise process control and inspection.

-

Fine-Pitch and Microelectronics Assembly

Capable of placing passives down to 0201s and 01005s, fine pitch to .04 mils, as well as BGA, µBGA, and VFBGA.

-

Flexible Build Volumes and Board Sizes

From a single prototype to mid-volume, Summit builds to your requirements.

-

Advanced Soldering Technologies

High-speed SMT lines with jet paste printing, vapor phase, and wave solder for clean, repeatable joints.

-

Comprehensive Inspection and Quality Control

3D X-ray, AOI, and flying probe testing verify connections meets IPC Class II and III standards.

-

Specialized Processes and Finishes

Support for RoHS and leaded assemblies, underfill, staking, conformal coating, and microelectronics integration for complex builds.

-

You've Placed an Order, What Happens Next?

What to Expect -

You've Decided to Supply Your Own Parts and/or Boards. What Process Should You Follow?

Five Steps to Preparing a Kit -

How to Prepare Your Files for Seamless Manufacturing.

BOM Best Practices -

Wondering When to Expect Your Boards? Learn More About Turn Times.

Turn Times Explained

We’re available to answer any questions

-

Email Us

info@summitinterconnect.com -

Call Us

+1 (877) 264-0343

Frequently asked questions.

-

-

Turnkey assembly centralizes procurement, manufacturing, and assembly under one supplier, which improves supply chain efficiency, reduces cost variability, and eliminates common handoff issues between vendors. It also allows for better quality control and adherence to IPC-A-610 Class 2 or Class 3 workmanship standards.

-

We source components only from vetted, authorized distributors to avoid counterfeit risk, maintaining full traceability for each part. Our supply chain team uses real-time market data to identify alternatives during shortages, ensuring on-time delivery without compromising compliance with customer or industry requirements.

-

Our turnkey process follows J-STD-001 for soldering quality and IPC-A-610 for assembly workmanship. Every board undergoes automated optical inspection (AOI), X-ray inspection for hidden solder joints, and in-circuit or functional testing to verify performance before shipment. Additionally, Summit sources components only from vetted, authorized distributors to avoid counterfeit risk, with full traceability for every part number. All components undergo incoming inspection to verify part numbers, quantities, and condition, ensuring compliance with customer specifications and IPC-A-610 Class 2 or Class 3 standards.

-

By consolidating board fabrication, component procurement, and assembly into one coordinated workflow, turnkey service eliminates delays caused by multi-vendor handoffs. Summit’s integrated scheduling and real-time production tracking allow for rapid prototyping and quick ramp to volume, reducing lead times from weeks to days.

We manufacture a broad range of PCB types and technologies for a one-stop solution

-

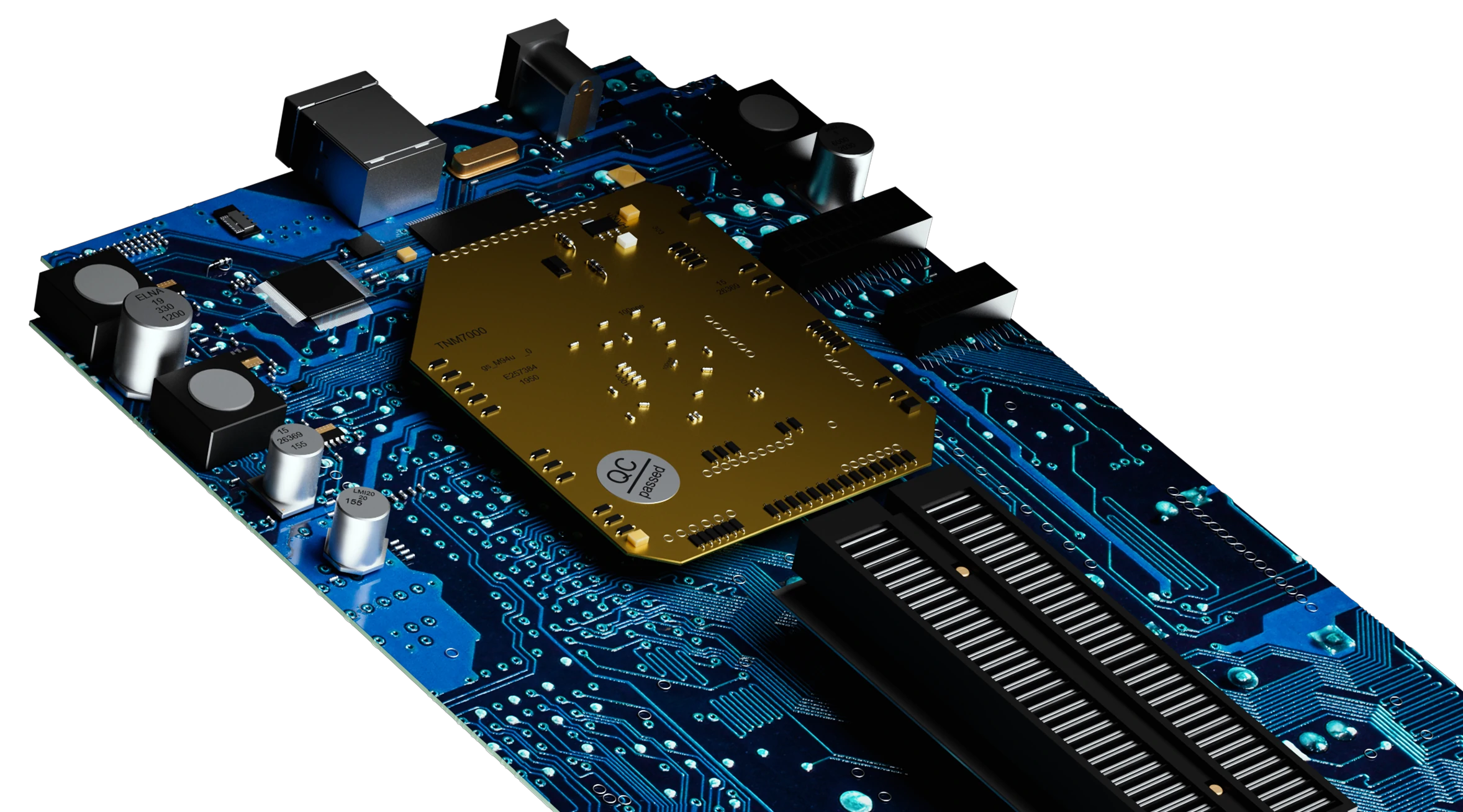

High-Density Rigid

Summit provides HDI rigid PCBs with microvias, blindburiedvias, back drilling, via fill, metal core, and large panel options.

-

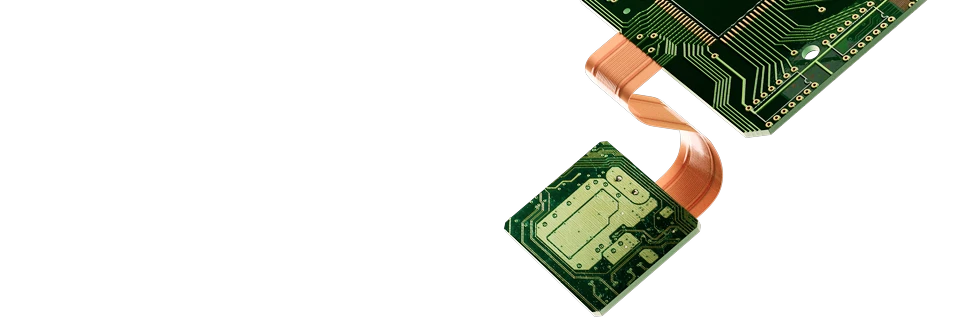

Rigid-Flex and Flex

As experts in rigid-flex and flex manufacturing, we handle rigid-flex, bookbinder, multilayer, adhesiveless & adhesive, stiffeners, laser ablation, thin flex laminates, assembly options and more.

-

RF / Microwave

We specialize in semiconductor reference cards, probe cards, DUT, and burn-in-boards. Our RF capabilities include high aspect ratio, low-loss materials, bondable gold, tight tolerance drilling, and sintering.

-

Thermal Management PCBs

Summit Interconnect manufactures thermal management PCBs with advanced materials and processes that optimize heat dissipation for reliable performance in demanding, high-power applications.

Additional assembly resources

-

Dec 16, 2025

Advanced Assembly Changes Name to Summit Interconnect

-

Dec 16, 2025

Reasons to Consider Full Turnkey PCB Assembly

-

Dec 16, 2025

From Layout to Fab: Gerry Partida’s Top DFM Guidelines for PCB Designers

-

Dec 16, 2025

6 Steps for an Accurate PCB Assembly Quote

-

Dec 16, 2025

Full Turnkey vs. Partial PCB Turnkey: What’s the Difference

-

Dec 16, 2025

Component Placement Guidelines in the Age of Automation

-

Dec 16, 2025

Strategies for Overcoming Component Shortages

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing