Bookbinding refers to the slight offset of flexible layers within a rigid-flex PCB stackup to reduce mechanical stress during bending. This technique prevents buckling or wrinkling in the flex area, improving long-term reliability in dynamic flex applications.

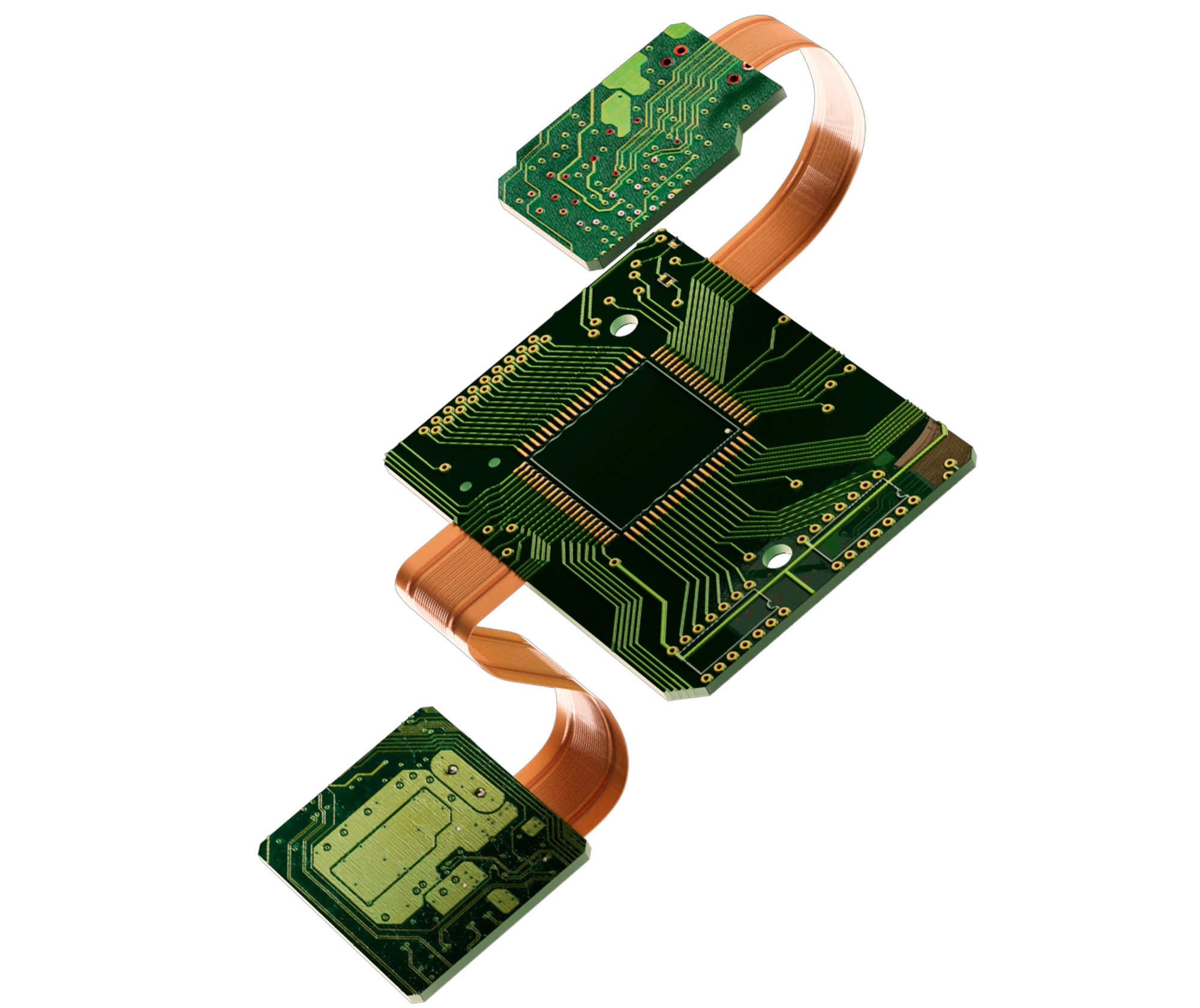

Rigid-Flex and Flex PCB Solutions

From simple flex to multilayer rigid-flex, Summit provides precision engineering and materials expertise for lightweight, space-saving, and mechanically resilient electronics.

Rigid-Flex

Rigid-flex PCBs combine the durability of rigid boards with the adaptability of flexible circuits, creating a single integrated design. By incorporating flexible layers into rigid stack-ups, designers can achieve lighter, smaller, and more mechanically robust assemblies for complex electronics.

Summit’s extensive experience with multilayer rigid-flex stack-ups, tight registrations, and advanced materials delivers manufacturable designs with proven electrical performance and mechanical reliability.

Key Attributes of Core or Standard Rigid PCBs

- Integrated rigid-flex layers create a unified construction

- Fewer connectors are required for simplified assembly and improved dependability.

- The lightweight, compact design saves space and reduces mass.

- Dynamic flex capability supports folding and repeated mechanical bending.

- High reliability is maintained under vibration, shock, and thermal stress.

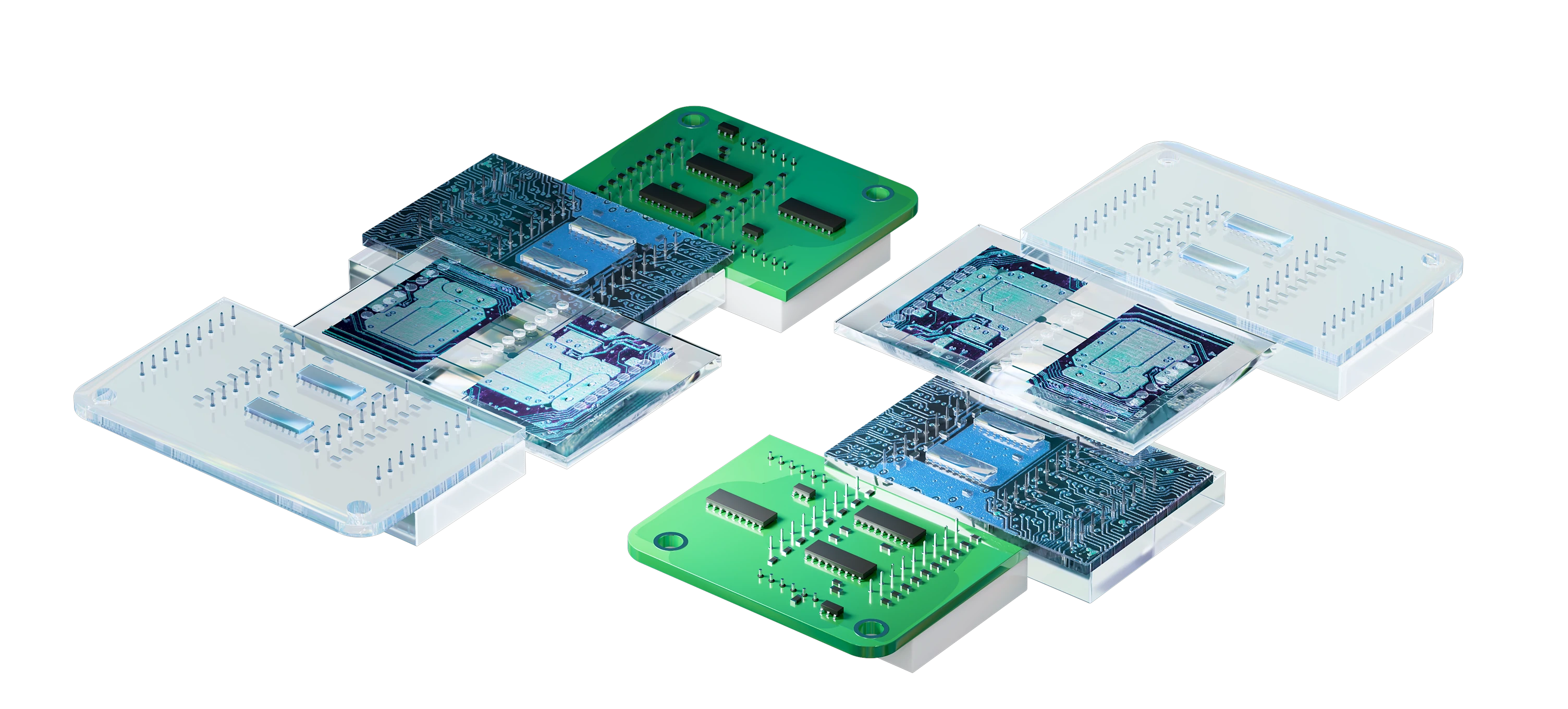

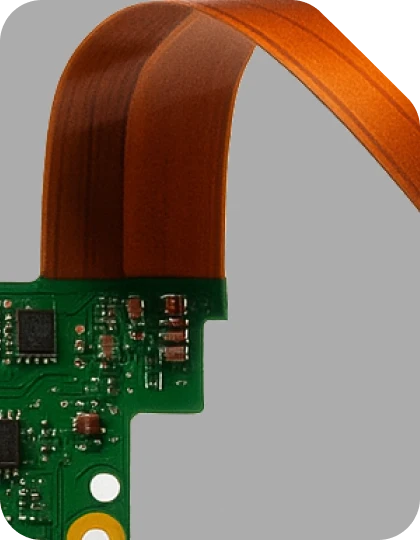

Flexible Circuit Boards

Flexible PCBs offer thin, lightweight interconnects that contour to unique shapes and fit tight packaging requirements. They minimize hardware, streamline assembly, and enable compact electronic designs.

Summit’s depth in multilayer flex, fine-line imaging, and advanced coverlay systems ensures durable, manufacturable solutions that deliver electrical precision and mechanical resilience in demanding form factors.

Key Attributes of Flex Circuit Boards

- Thin polyimide films enable ultra-compact designs.

- Fewer interconnects simplify builds and lower risk.

- Lightweight circuits conserve space in tight enclosures.

- Bendable formats adapt to complex geometries.

- Single-sided, double-sided, multi-layer flex

Rigid-flex and flex capability highlights

-

High-Layer Count Rigid-Flex Builds

Complex, multilayer rigid-flex boards with tight bend requirements. Summit delivers 20+ layer rigid-flex builds for aerospace, defense, and high-reliability markets.

-

Bookbinder Technology

Staggered flex layers achieve tight bends without stress, cracking, or buckling. Our engineering processes allow precise bend radius.

-

Adhesive and Adhesiveless Constructions

Experience with both flex construction types matches thickness, flexibility, durability and signal integrity needs for mission-critical designs.

-

Laser-Drilled Microvias

Controlled drilling produces high-accuracy microvias. Summit state-of-the-art laser drilling supports fine-pitch requirements in rigid-flex designs.

-

Stiffeners

Reinforced rigid areas for durability, flatness, and assembly handling. Precision stiffener integration ensures stability and manufacturability.

-

Advanced Materials Expertise

Polyimides, adhesiveless laminates, and hybrid stack-ups for harsh environments. Decades of flex material experience ensures reliable performance.

Rigid-Flex Overview

This presentation covers the benefits, materials, processing, design considerations, and reliability challenges of flex and rigid-flex PCBs.

We’re available to answer any questions

-

Email Us

info@summitinterconnect.com -

Call Us

+1 (877) 264-0343

Frequently asked questions.

-

-

Flex and rigid-flex designs rely on polyimide films, adhesiveless copper foils, and specialized coverlays for flexibility and durability. Material selection affects bend radius, thermal performance, and electrical stability, making it a critical part of the design process.

-

Yes. Summit offers full assembly services for both flex and rigid-flex PCBs, including component placement, soldering, and inspection. We follow IPC-A-610 workmanship standards and use specialized fixturing and handling processes to protect flexible circuits during assembly.

-

Rigid-flex PCBs eliminate connectors and cables between rigid sections, reducing weight, improving signal integrity, and enhancing mechanical reliability. They are ideal for compact, high-reliability systems like medical devices, aerospace electronics, and wearable tech.

-

Yes. Summit has extensive experience producing multi-layer rigid-flex PCBs with complex layer counts, multiple flex sections, and precise bend requirements. Our engineering team works closely with customers to optimize stackups, material usage, and manufacturability.

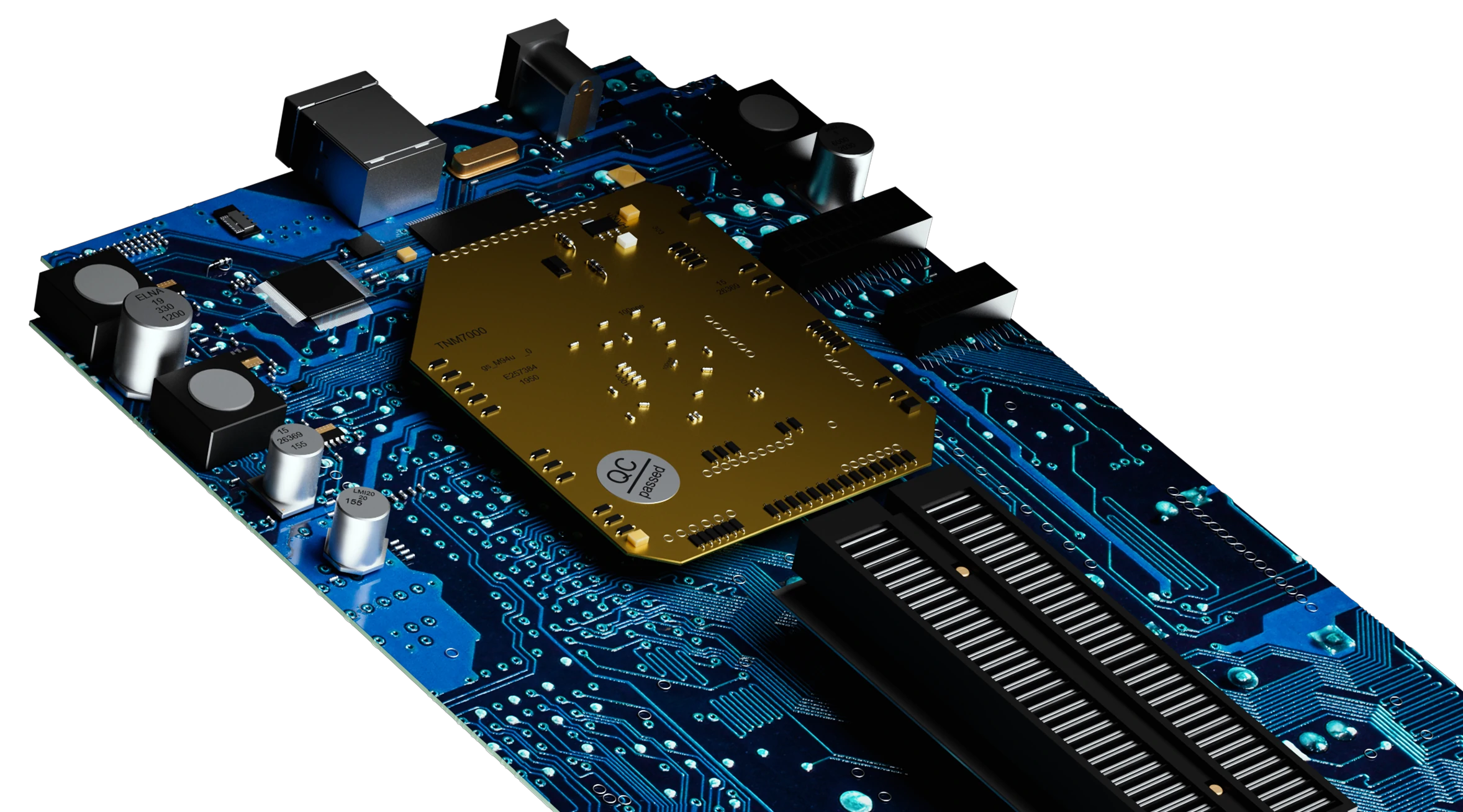

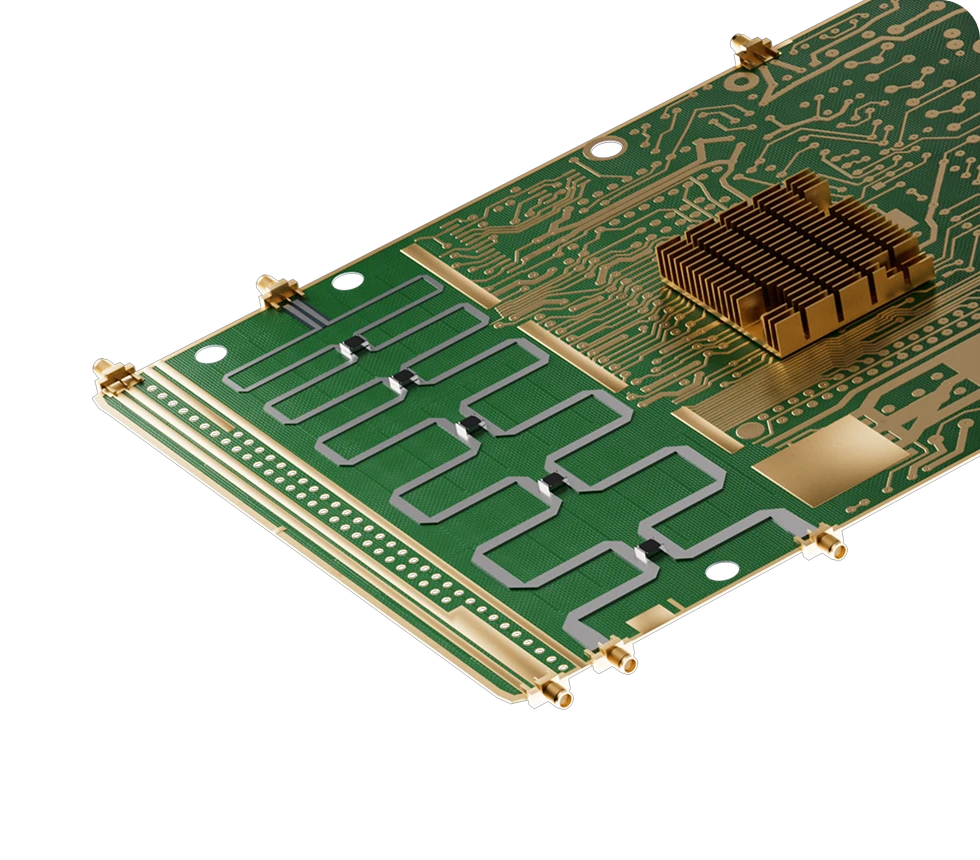

We manufacture a broad range of PCB types and technologies for a one-stop solution

-

RF / Microwave

We specialize in semiconductor reference cards, probe cards, DUT, and burn-in-boards. Our RF capabilities include high aspect ratio, low-loss materials, bondable gold, tight tolerance drilling, and sintering.

-

Prototype Assembly

Looking to test your design before committing to a full PCB production run? Small-quantity prototype PCBs are manufactured with the same state-of-the-art equipment and quality processes used for production runs.

-

Thermal Management PCBs

Summit Interconnect manufactures thermal management PCBs with advanced materials and processes that optimize heat dissipation for reliable performance in demanding, high-power applications.

-

High-Density Rigid

Summit provides HDI rigid PCBs with microvias, blindburiedvias, back drilling, via fill, metal core, and large panel options.

Additional flex resources

-

Dec 16, 2025

Don’t Overlook the Advantages of Rigid-Flex Boards

-

Dec 16, 2025

Six Types of Printed Circuit Boards & Their Applications

-

Dec 16, 2025

Selecting the Best PCB Material for High-Speed Applications

-

Dec 16, 2025

8 Trends in Advanced PCB Fabrication

-

Dec 16, 2025

Kapton: Applications & Benefits in PCB Manufacturing

-

Dec 16, 2025

Next Progression in Microvia Reliability Validation

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing