Why UL Certification Matters for PCB Safety & Compliance

One of the most recognized safety certifications in the electronics industry is Underwriters Laboratories (UL) Certification. UL certification ensures that PCBs meet strict flammability, electrical, and mechanical safety standards, which is crucial for product reliability, regulatory approval, and market acceptance.

What is UL Certification?

UL (Underwriters Laboratories) is an independent global safety certification organization that evaluates products for compliance with recognized safety standards. For PCBs, UL certification primarily focuses on:

- Flammability Ratings (UL 94)

- Material Safety

- Dielectric Withstanding Voltage

- Temperature and Thermal Performance

- Traceability & Compliance

Why is UL Certification Important for PCBs?

Ensures Fire Safety

UL 94 is a widely used standard that classifies plastics based on their flammability characteristics. PCBs must meet fire resistance requirements to prevent catastrophic failures in electronic devices. UL 94 testing supports UL 796 certification for printed wiring boards.

The most common UL 94 ratings for PCB base materials include:

- UL 94V-0: Self-extinguishing within 10 seconds, no flaming drips.

- UL 94V-1: Self-extinguishing within 30 seconds, no flaming drips.

- UL 94HB: Slow-burning, horizontal testing method.

Regulatory & Industry Compliance

Many industries, including automotive, aerospace, medical, and industrial electronics, require UL-recognized PCBs to meet government and regulatory standards. PCBs are most often certified as UL Recognized Components rather than UL Listed products. UL Recognized marks assure OEMs and regulators that the PCB materials and manufacturing processes comply with applicable safety guidelines.

Increases Market Acceptance & Trust

UL-recognized PCBs are preferred by OEMs and contract manufacturers as they signal reliability and adherence to safety standards. Consumer and customer confidence increases when electronic products use UL-certified components.

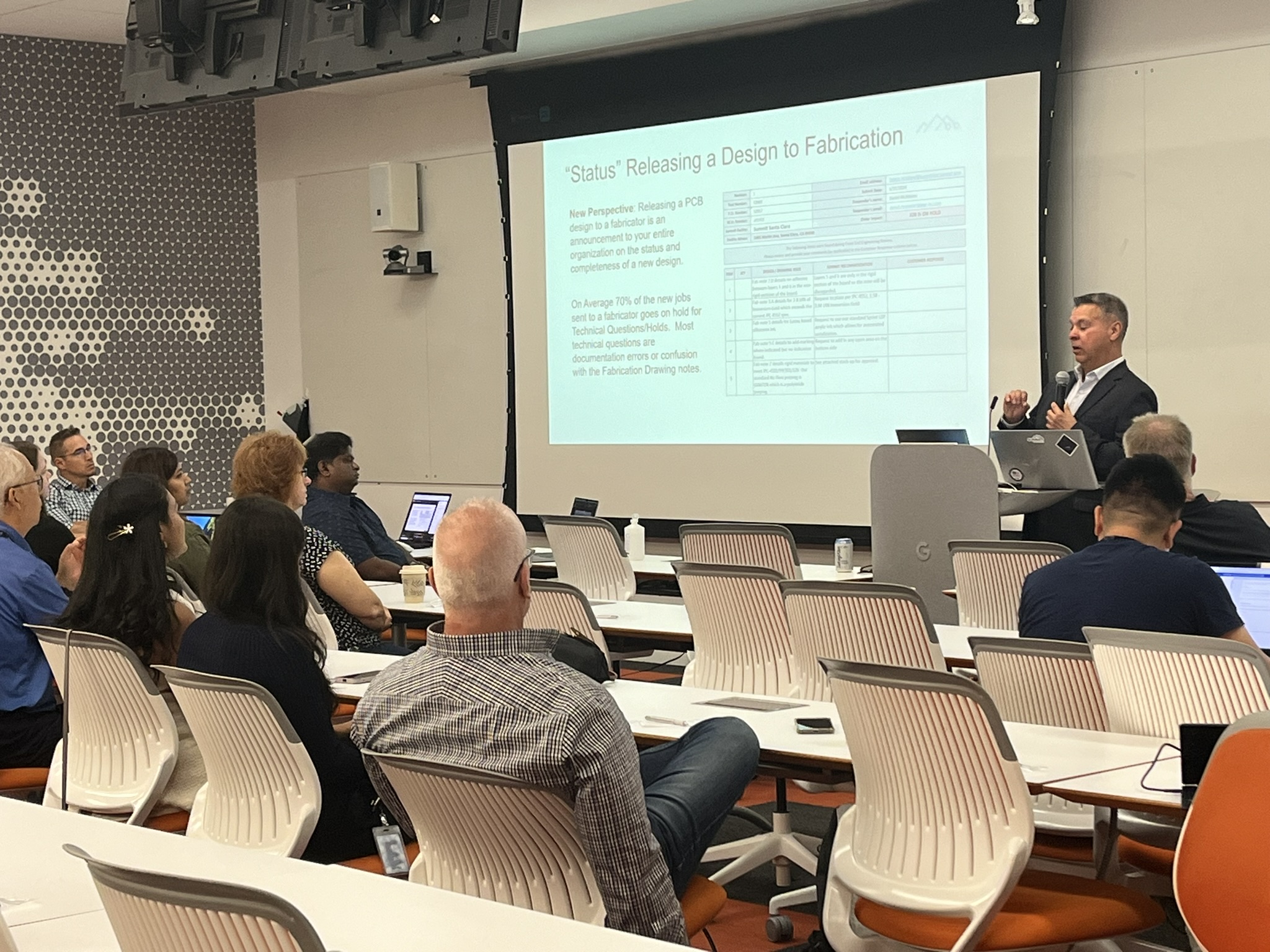

Ensures High-Quality Manufacturing Processes

UL certification requires manufacturers to undergo stringent testing and regular inspections under UL’s Follow-Up Services program. This improves production consistency, reduces failure rates, and enhances long-term reliability.

Key UL Standards for PCB Certification

- UL 796 – Standard for Printed-Wiring Boards

Governs the safety of rigid and flexible PCBs; evaluates dielectric strength, thermal resistance, and electrical performance. - UL 94 – Flammability Testing for Plastics

Determines how PCB laminates respond to fire and supports UL 796 compliance. - UL 746E / UL 746C – Polymeric Materials for PCBs

Defines electrical, environmental, and thermal performance of PCB base materials, including RTI (Relative Thermal Index) and CTI (Comparative Tracking Index). - UL 62368-1 – Safety Standard for ICT and AV Equipment

Applies to IT, telecom, and consumer electronic devices. Replaces the now-obsolete UL 60950-1 standard.

How to Obtain UL Certification for PCBs

To obtain UL certification, PCB manufacturers must undergo a rigorous testing and inspection process:

- Material Testing – Flame resistance, temperature endurance, electrical performance.

- Factory Inspection – UL representatives audit facilities for compliance with approved materials and processes.

- Dielectric & Electrical Testing – Verification that PCBs can withstand high voltages without breakdown.

- CTI/RTI Verification – Assess tracking resistance and long-term thermal reliability of materials.

- Long-Term Compliance Audits – Manufacturers undergo ongoing UL audits to maintain recognition.

Challenges of Achieving UL Certification

While UL certification is highly beneficial, manufacturers may face challenges such as:

- Cost of Compliance – Investment in testing, materials, and inspections.

- Time-Consuming Process – Certification can take weeks or months, affecting production timelines.

- Material Restrictions – PCB stackups or laminate selections may need modification to comply with UL standards.

Conclusion

UL certification is a critical requirement for PCB manufacturers that want to ensure safety, reliability, and compliance with industry standards. Whether for consumer electronics, industrial equipment, medical devices, or aerospace applications, UL-recognized PCBs provide assurance of fire resistance, electrical integrity, and regulatory compliance. UL’s Yellow Card database allows OEMs to verify certified laminates and PCB fabricators. Investing in UL certification enhances credibility, expands market access, and reduces risks from substandard materials or processes.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing