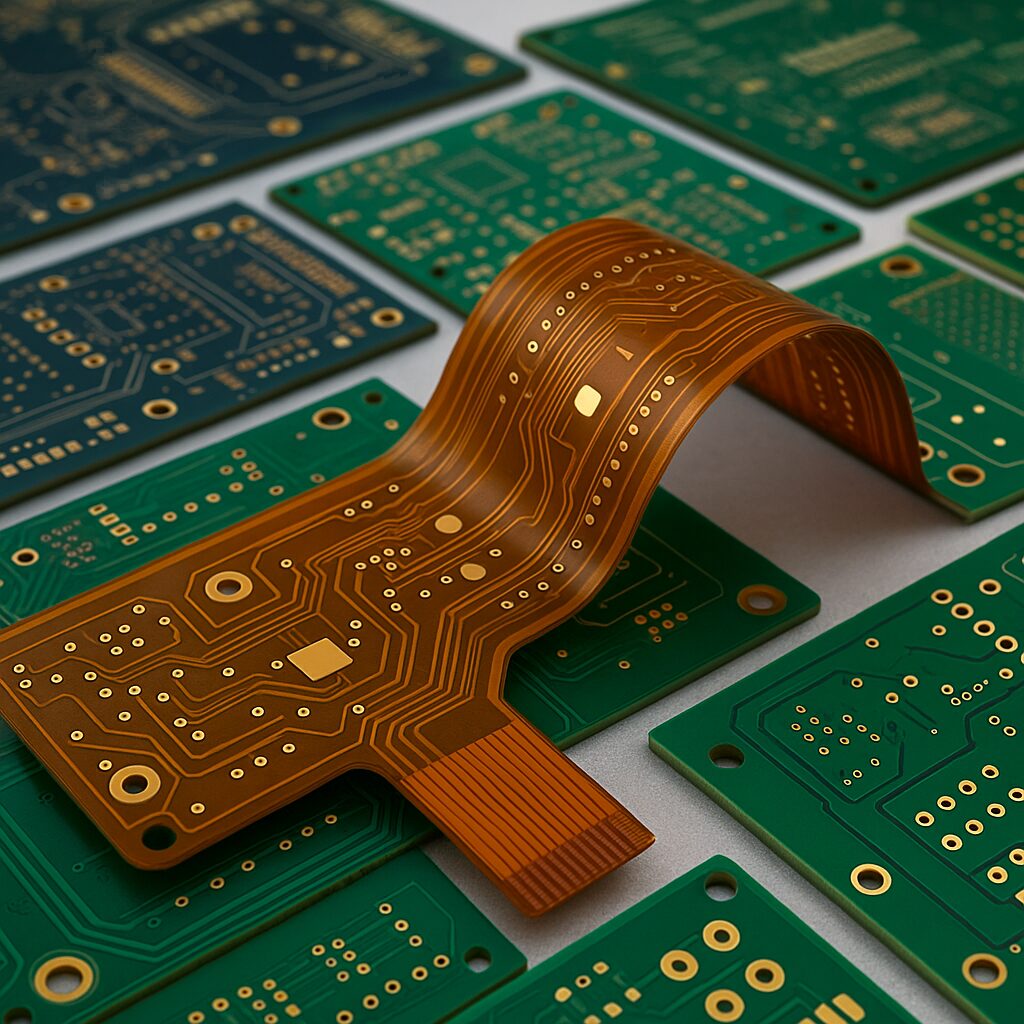

Selecting the right rigid-flex PCB manufacturer is central to reliability, yield, and schedule. As demand for flex and rigid-flex circuit boards grows in aerospace, medical, automotive, and defense, you need a partner that can meet IPC requirements, support complex stackups, and scale from quick-turn PCB prototypes to production. For teams seeking a US-based, PCB manufacturer pay close attention to the 5 criteria below when evaluating fabrication partners:

1) Experience and Technical Expertise

Prioritize suppliers with proven builds in single-sided, double-sided, multilayer flex, and rigid-flex. Ask for examples using adhesiveless polyimide, controlled-impedance routing, microvias, and via-in-pad on flex. Strong partners should also offer DFM support that catches items such as bend-radius violations, coverlay windowing, annular ring risk on small vias, or stiffener registration before release.

Relevant IPC references

-

IPC-2223: Sectional design standard for flexible printed boards

-

IPC-6013: Qualification and performance for flexible and rigid-flex printed boards

-

IPC-4202/4203/4204: Materials for flexible base, adhesives, and coverlay

-

IPC-2221 (and 2221B): Generic design rules that still apply to rigid portions in rigid-flex

-

IPC-6012: Performance spec for rigid sections in rigid-flex circuit boards

-

IPC-4761: Via protection types, useful when defining plug, cap, or fill strategies in flex-to-rigid transitions

2) Manufacturing Capabilities

Flex and rigid-flex designs require process control beyond standard rigid PCB fabrication manufacturers. Confirm that the company’s capabilities meet your requirements in the following areas:

- Minimum trace/space per copper weight and layer type, including fine-line on polyimide

-

Laser drilling specs for microvias, smallest mechanical drills, aspect ratio limits, and any pcb backdrilling support on rigid areas

-

Controlled impedance methods with coupon design and measurement tolerance

-

Coverlay design rules, windowing clearances, and solder mask usage on rigid areas

-

Stiffeners: FR-4, PI, stainless, or aluminum, including adhesive thickness control

-

Surface finishes: ENIG, ENEPIG, immersion Ag, hard gold for wear on flex connectors

3) Quality Assurance and Certifications

For high-reliability applications, verify the PCB partner can provide:

-

AS9100D / ISO 9001 quality systems

-

ITAR/EAR control as needed

-

Build acceptance to IPC-6013 (flex) and IPC-6012 (rigid portions), with Class 2 or Class 3 as appropriate

-

Electrical test per IPC-9252, AOI on fine lines, X-ray for hidden features, and micro-sectioning for copper/plating integrity and annular ring analysis

-

Material traceability for Class 3

4) Supply Chain and Lead Time Integrity

A strong PCB manufacturer partner maintains inventory depth on polyimide cores, copper foils, and low-flow bondplies to avoid shortages. Look for:

-

Quick turn PCB options for prototypes, plus predictable standard and expedited lead times

-

Stable laminate sourcing

-

Transition support from proto to production with consistent engineering support

5) Cost Versus Value

Lowest unit price rarely equals lowest total cost. Value is created through:

-

Engineering collaboration and DFM that improves yield

-

Smart panelization to reduce scrap

-

Clear NRE, test, certification, and expedite pricing

-

Guidance on design versus cost tradeoffs

Questions to Ask Before You Make a Final Decision

- Which IPC classes do you support for flex or rigid-flex builds?

- Can you share cross-sections or micrographs of recent flex builds?

- Do you perform 100% electrical testing on every layer?

- How do you control registration during multilayer lamination?

- Are stiffeners bonded with controlled thickness adhesives or PSA?

- What’s your process for impedance verification (coupon or couponless)?

- How are bends and dynamic-flex regions inspected for cracks or delamination

Choosing a flex PCB supplier isn’t just a sourcing decision; it’s a design partnership. The right manufacturer brings DFM expertise, IPC-certified processes, traceable quality, and scalable capacity that ensure your flexible circuits perform reliably across hundreds of thousands of flex cycles.

A partner who understands IPC-6013 Class 3, dynamic-bend reliability, and high-density rigid-flex construction will help you achieve both mechanical durability and electrical performance from prototype through production.

Strong collaboration early in design = fewer redesigns, faster builds, and higher reliability in the field.

Click here to learn more about Summit’s rigid-flex and flex solutions.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing