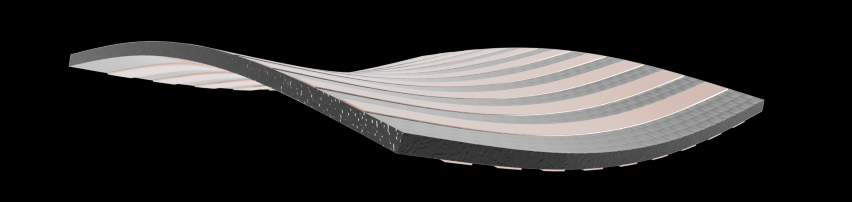

New designers tend to remove a great deal of copper from their boards. The problem with this approach is that without copper present in equal amounts on mirror-layers of the circuit board that constrain the expansion of the dielectric layers equally, the printed circuit board can warp during convection reflow.

Unless you are designing high-voltage circuits that have specific creepage and clearance requirements, you’ll want to leave as much copper as possible on your board to prevent this. The way to do that is with copper pours. You can use copper pours, both large and small, to cover parts of your board and prevent this warpage.

Here’s an example of the difference between a board with copper fills and board without them. On this board, there is so little copper that warpage is likely not going to be a problem with or without copper fills.