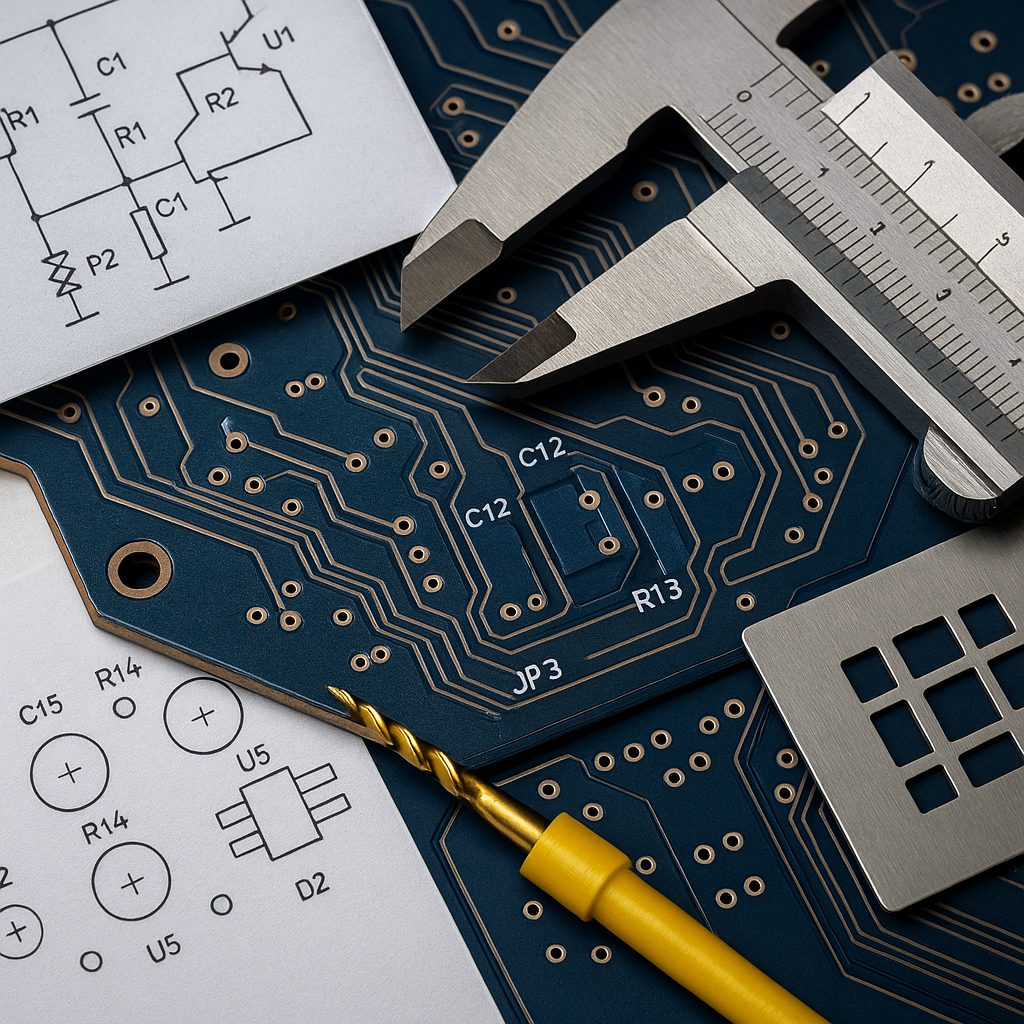

Summit Interconnect’s Hollister facility has recently enhanced its quick-turn PCB prototyping capabilities by installing the TiTAN PSR-H Direct Imaging (DI) system. This advanced equipment, developed by CBT and supplied by Technica USA, is renowned for its high-speed, high-resolution imaging capabilities, particularly for photoimageable solder masks.

The TiTAN PSR-H model offers several key features:

- High-Speed Imaging: Recognized as the fastest in its class for all photoimageable solder masks, including standard, black, and white variants.

- Versatility: Capable of handling both dry film and solder mask printing with exceptional front-to-back registration accuracy.

- Precision: Delivers print resolutions down to 10 microns, powered by CBT’s patented technology.

This installation aligns with Summit Interconnect’s commitment to integrating cutting-edge technology across its facilities to meet the evolving demands of the PCB industry. The Hollister site, known for specializing in 24-hour quick-turn PCB prototyping, will benefit from the TiTAN system’s capabilities, ensuring faster turnaround times and enhanced quality for complex PCB designs.

By investing in such advanced imaging technology, Summit Interconnect reinforces its position as a leading provider of high-reliability, advanced technology printed circuit boards in North America. This move not only boosts the Hollister facility’s operational efficiency but also enhances its ability to serve industries requiring rapid prototyping and precision manufacturing.