Here is a fun post on PCB registration and Staying on Target!

Drill and layer to layer registration can be a complex and challenging goal in the manufacturing of a PCB. In my 37 years in the industry and my visits to over 100 worlds (PCB facilities). I have seen many wild approaches to registration, and found few fabricators that have truly mastered the complete registration process.

“Kid, I’ve flown from one side of this industry (galaxy) to the other, and I’ve seen a lot of strange stuff,”

PCB layer to layer and drill registration requires a deep understanding of literally all the moving parts. Material shrinks during lamination and it differs by thickness, resin type, glass construction and amount of lamination cycles. This is followed by drill operations, tooling methods and operator actions.

“The Registration Accuracy (Force) is what gives a fabricator (Jedi) his power. It’s the data collection (an energy field created by all living things). It surrounds us and penetrates us. It binds all of the drills, lands and layers (the galaxy) together.”

The following is a few light hearted Star Wars references to PCB registration. By no means is it a PCB fabricator tutorial on how to manage registration. This is just some fun on PCB registration and “Staying on target!”

LDI (Laser Direct Imaging) provides tremendous improvements for the processing of PCB layers. It improves the front to back registration of a core but it is still dependent on the correct core scaling that is needed for compensating lamination shrinkage.

Lamination and shrinkage.

“One thing for sure, we are going to be a lot thinner”.

During the lamination process the laminate material will shrink in size. An advanced PCB fabricator actually has retained shrinkage information for each resin system, core thickness, core constructions, prepreg and multiple lamination cycles. If your fabricator does not have this information or can’t explain how they manage it, well they might not be an advanced PCB fabricator.

A fabricator that does not use the most advanced targeting and data collection methods is like Luke turning off his targeting computer. Did you ever notice that Darth Vader never turned off his targeting system? An image from Darth’s cockpit for objective evidence.

Turning off the targeting computer is like being Ty Webb from CaddyShack.

When we use all of our data, and effectively use our targeting systems and methods we are able to achieve excellent registration. If we don’t think and let things happen, we usually will end up with a mountain of scrap due to bad registration.

I can make fun of farm boys since I was once one.

Sometimes a design is asking for registration that can’t be achieved.

Sometimes it’s wiser for the fabricator to walk away from a bad design that can’t be registered.

If the design doesn’t follow IPC-2221, IPC-2222 or IPC-2223 guidelines your design, program, career or company could end up like this Tie Fighter. If a knowledgeable fabricator is concerned about registration, please listen to their advice.

When we do pull off a complex job and meet the registration, I would love to get the customer’s feedback on the job well done.

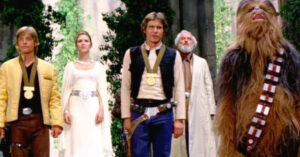

For the most part we are just like Chewy at the end of the original Movie at the award ceremony without a medal.

Maybe he was screaming out loud “where is my medal?” I don’t know, I don’t speak Wookie.

I hope you enjoyed the post. I was 13 years old when the first movie came out and I’m glad to see that it has entertained us all these years.

Well that’s it for now. I need to commence my bombing run on a high aspect ratio PCB with multiple lamination cycles, with a drill diameter that is too small, that wobbles, and an annular ring that should have been bigger, with no time to make a remake… “So let’s tighten up the formation, set your deflector shields to double front, and watch out for those Tie fighters. It will be just like Beggar’s Canyon back home”!

Special thanks to the following friends for their ideas on this post:

Mario Cortez

Daniel Heitner

Michael Lowry

Todd Maertz