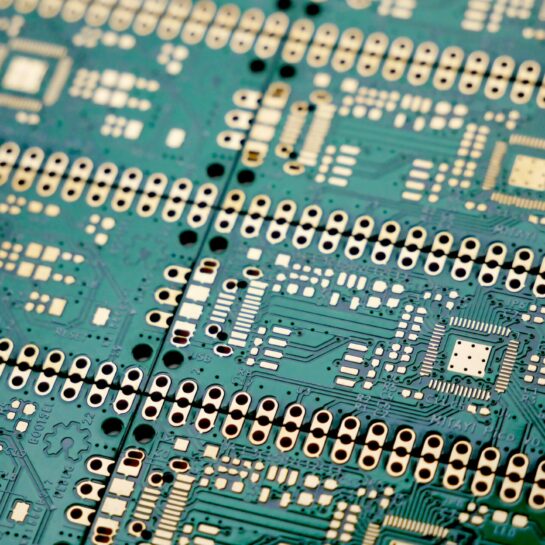

Printed circuit boards come in three different styles: single-sided, double-sided, and multilayered. For the purposes of this article, we will focus on single and double-sided PCBs. In the world of circuit boards, single- and double-sided are terms used to describe a PCB’s complexity. There are different price points and applications depending on the type of PCB. Below, we will answer the important question of single vs. double PCBs: what is the difference?

Single-Sided PCBs

Single-sided or single-layer PCBs feature one layer of conducting material (usually copper) on one side and the actual board with electronic components on the other. These circuit boards are typically affordable to make and, thus, are cost-effective for manufacturers of electronic devices. Their lack of complex components makes them easy to build, which—along with their reasonable price points—make single-layer PCBs some of the most popular boards out there. You can find these circuit boards in applications such as:

- Cameras

- Stereos

- Calculators

- Printers

- Surveillance systems

Double-Sided PCBs

These slightly more complex PCBs feature electronic components on both sides of the circuit board, sandwiched over a conductive layer (also usually made from copper). The dual layers enable electrical currents to travel from one side of the board to the other. Featuring twice as much space for electrical components, these PCBs can be constructed with more complex circuitry than single-sided boards. Double-sided PCBs can be found in:

- Vending machines

- Vehicle dashboards

- Industrial controls

- Single vs. Double PCBs

When placed side by side, the differences between single- and double-sided PCBs are plentiful. While they serve the same function, single-sided PCBs are much simpler in nature than double-sided circuit boards. Single PCBs are more affordable due to their quick and easy build, while double PCBs are more expensive due to their complexity.

For more information about single- and double-sided PCBs or to inquire about turnkey PCB manufacturing solutions, reach out to the experts at Summit Interconnect.