In the waning days of the Covid-19 pandemic, Advanced Assembly (Denver, Colorado) and Royal Circuit Solutions (Hollister and Santa Fe Springs, California) partnered together to gather insights on current state of the printed circuit board industry.

Each company sent survey requests to all current contacts inviting them to share perspectives on the industry and their related PCB service needs. 672 US-based engineers and buyers completed the survey, providing important industry facts, statistics, and advice for other PCB designers.

Here is a look into the current state of mind of PCB designers and buyers nationwide.

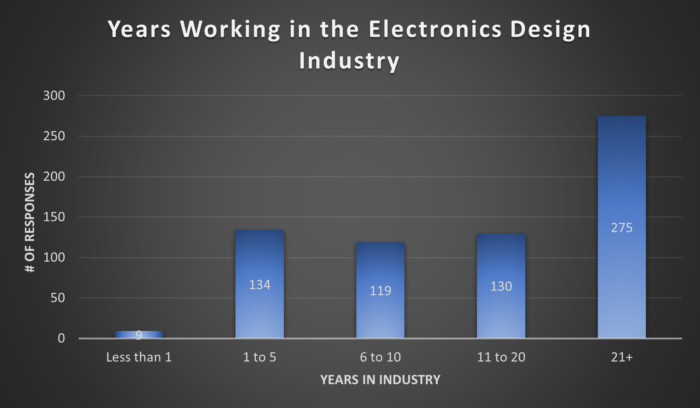

A DEPTH OF EXPERIENCE

Nearly 60% of today’s design engineers are 45+ years old with an average of 19 years of experience. These engineers work on at least 2 new product design each month and order board quantities of 200-300. The survey also highlights younger engineers with less experience seeking smaller companies for first jobs rather than large companies.

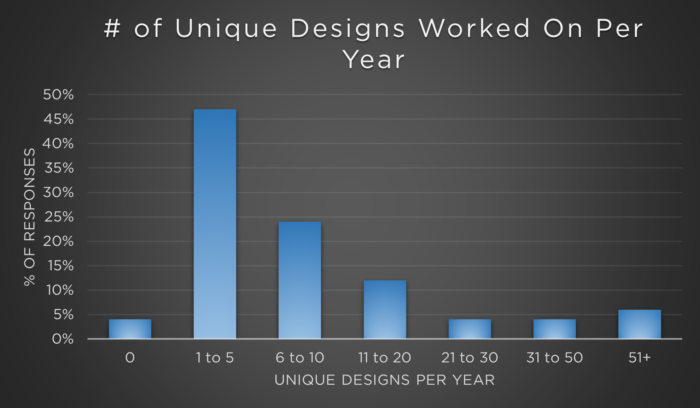

A STRONG FOCUS ON U.S. INNOVATION

PCB prototypes rarely move to production on the first try. Engineers typically revise boards 2 or 3 times before finalizing their designs. As designers continue to push the boundaries on size and complexity, the need for US-based prototype manufacturing should continue to grow. A focus on new product introductions also explains why PCB orders of 10 or less are the most requested quantities.

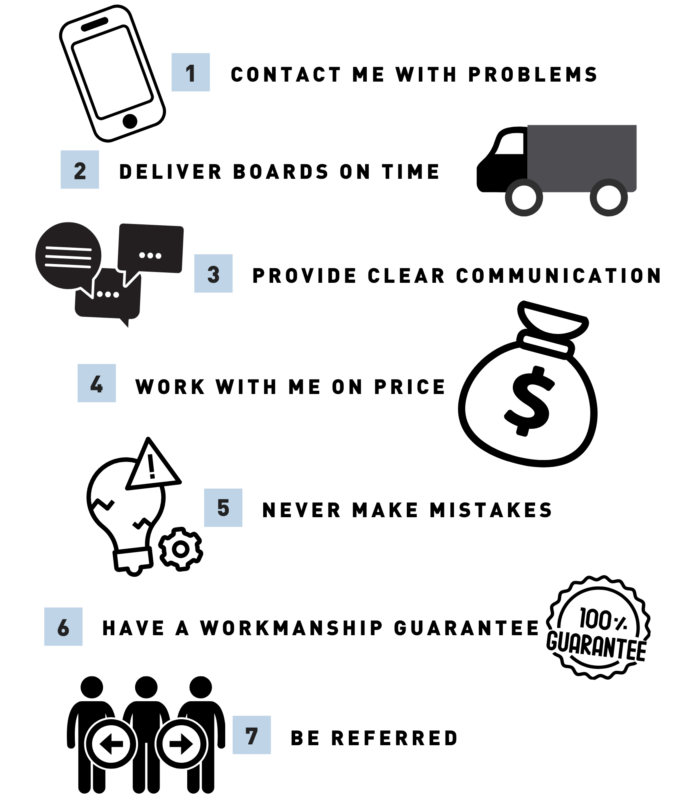

A NEED FOR SPEED AND SERVICE

Design engineers want boards delivered on time and a person to talk to when they need help. Interestingly, this need for speed and service was the same when engineers were asked a similar question 10 years ago. The most important criteria engineers look for in a PCB partner are:

1. Contact me when problems occur and solve them quickly.

2. Deliver boards on time.

3. Provide clear and consistent communication.

A CHANGE IN THE DESIGN PROCESS

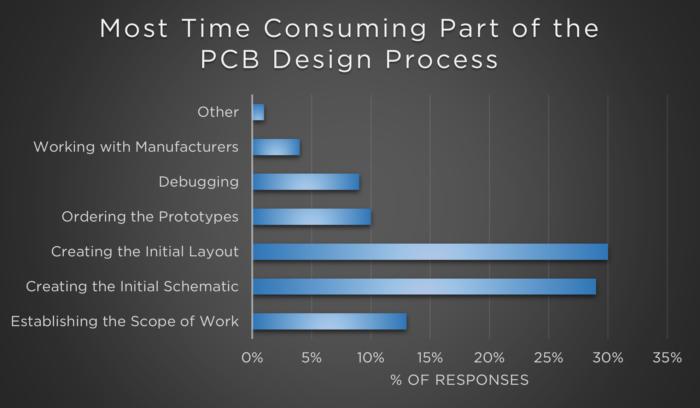

Ten years ago, the most time-consuming part of the PCB design process was purchasing parts and boards. Today, turn-key providers like Advanced Assembly and Royal Circuit Solutions have made it easy to order boards, components, and assembly all with one purchase order and point-of-contact. With these hassles taken care of designers can focus on the time-consuming tasks of creating initial layouts and schematics; and of managing changing requirements.

A SHIFT IN TECHNOLOGY

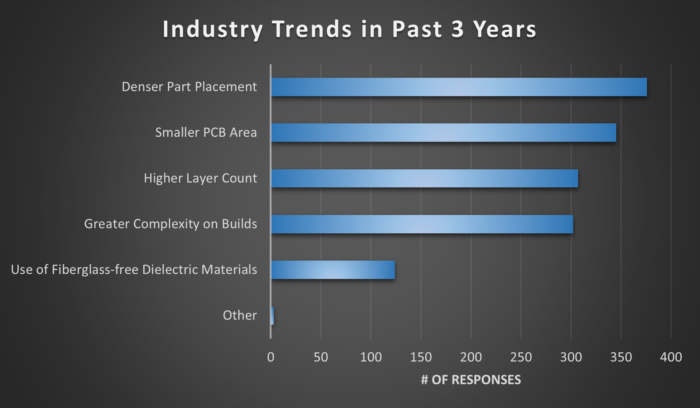

In the past three years, buyers and engineers have seen a move toward greater PCB complexity. More specifically, trends include denser part placements, smaller PCB areas, and higher layer count. Despite this evolution in technology, 35% of people interviewed still hand-assemble their PCB projects. As these trends continue, hand-assembling an entire build will become even more difficult.

A COMMUNITY WILLING TO HELP EACH OTHER

When asked for cost-saving tips or advice to share with fellow designers, participants were generous in their responses. Suggestions included general design tips, designing for manufacturing, the importance of flexibility, how to manage deadlines, and ways to reduce cost.

To read the tips and access further details on the survey findings, download the report.

Download Free Report Here