As customers and OEMs demand higher currents and increased operating temperatures, the need for heavy copper in PCB stack-ups has grown significantly. However, this presents challenges on the manufacturing side, where thicker copper layers can lead to lamination cracks or voids. Only a select group of suppliers has the specialized expertise to address these issues effectively, making it a niche area within the industry.

Over the years, Summit has established itself as a leader in the heavy copper lamination process, consistently delivering exceptional results. Our cutting-edge approach to heavy copper lamination enables us to expertly handle even the most demanding requirements, such as laminating 4 oz copper, while ensuring precision and quality in every aspect, including drilling. This capability allows us to meet the rigorous standards of industries that require robust and reliable PCB solutions, solidifying Summit as a trusted partner for your most challenging projects.

At Summit, we continually invest in the latest technologies and processes to ensure we stay at the forefront of PCB manufacturing. Our experienced team works closely with customers to develop tailored solutions that meet their specific performance requirements, no matter how complex. With a focus on quality control and on-time delivery, Summit has built a reputation for reliability, making us the go-to partner for OEMs and customers looking for long-term solutions to meet evolving industry demands.

IPC-6012 (Qualification and Performance Specification for Rigid Printed Boards) and IPC-6018 (Qualification and Performance Specification for High Frequency (Microwave) Printed Boards), along with the Space Addendum, all address the manufacturing standards and requirements for printed circuit boards (PCBs). Summit meets all manufacturing standards and requirements for 4 oz Copper IPC.

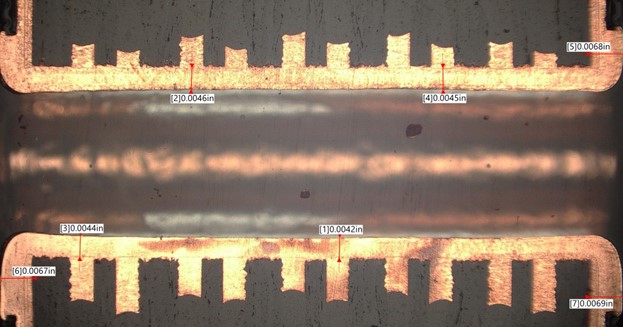

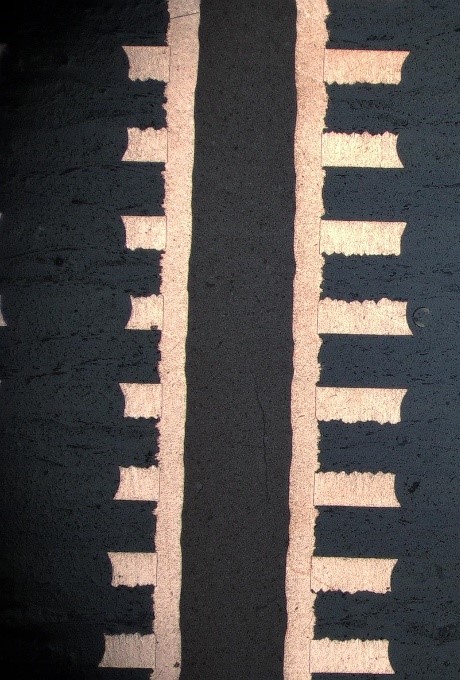

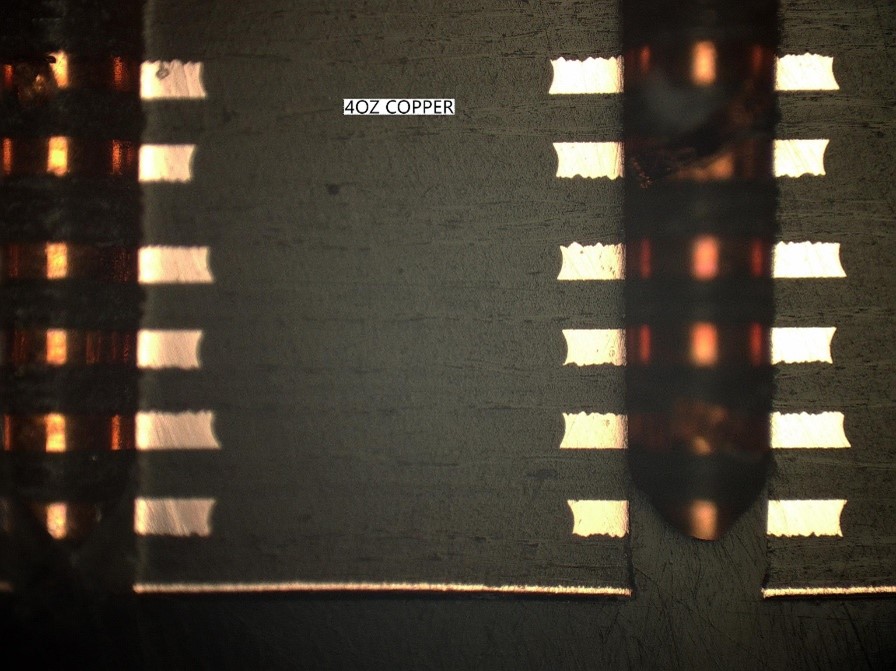

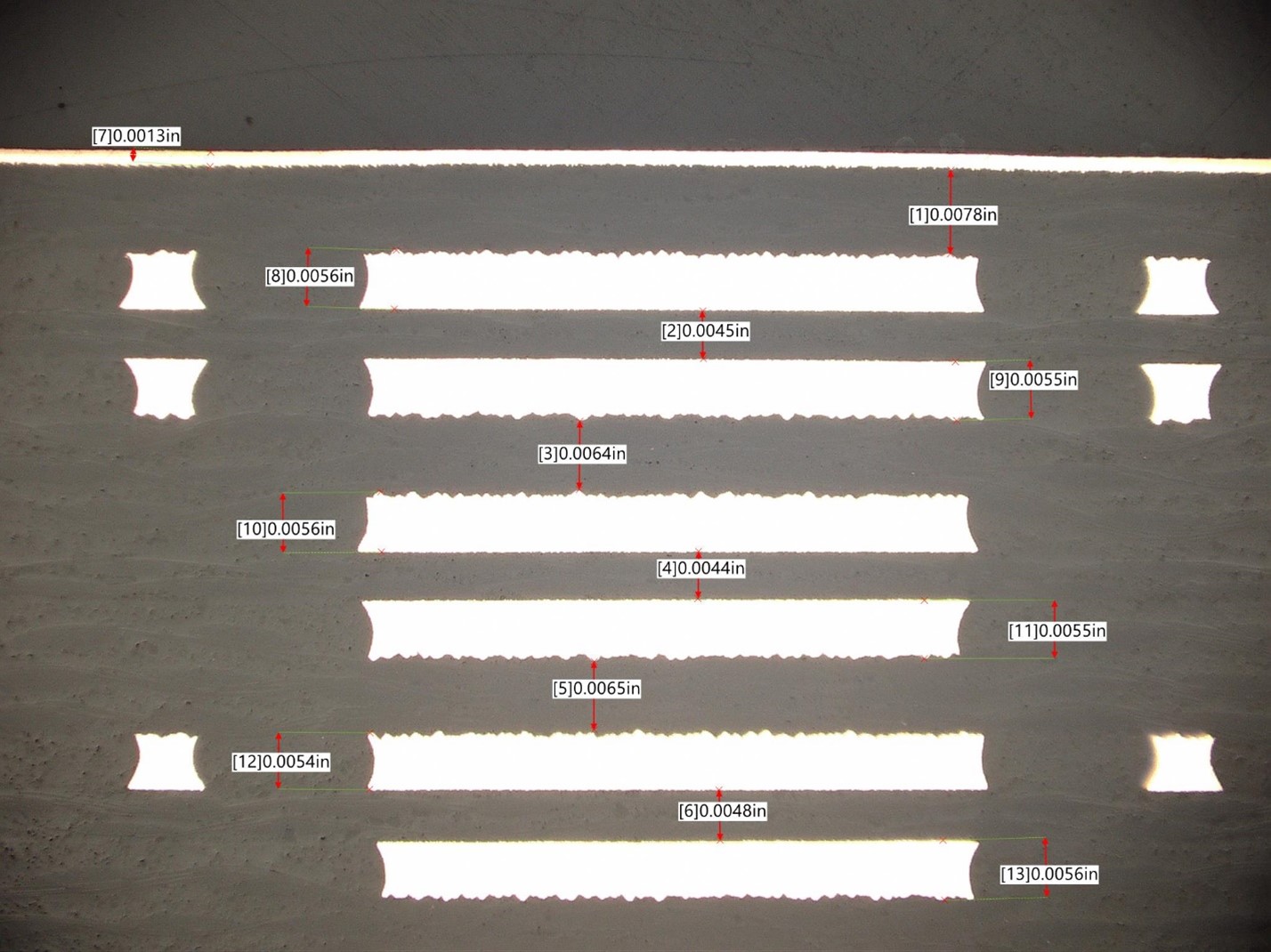

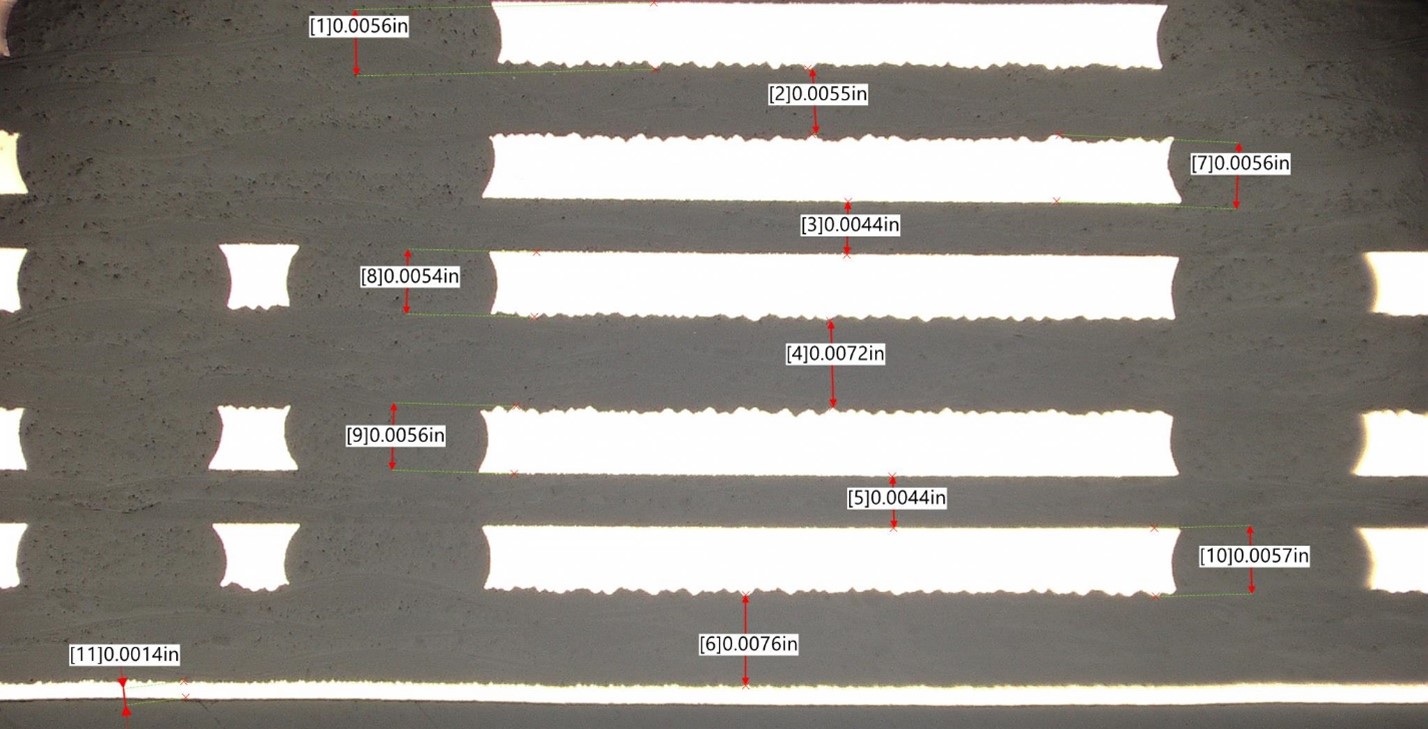

Picture below are from a 12 Layer all 4oz Copper job.

Coupon Plating