Proper file preparation is critical for successful PCB fabrication, ensuring accuracy, efficiency, and manufacturability. Before production, manufacturers require specific design files that provide information about layers, drill holes, component placement, and routing. Below is a checklist of essential files for PCB fabrication.

1. Gerber Files (RS-274X Format)

Gerber files define the copper layers, solder mask, and silkscreen details. They include:

- Top and Bottom Copper Layers: Defines circuit traces and pads.

- Solder Mask Layers: Covers copper traces, exposing only pads for soldering.

- Silkscreen Layers: Component labels, logos, and reference designators.

- Paste Mask Files: Used for stencil creation in Surface Mount Technology (SMT) assembly.

2. NC Drill Files

Drill files provide hole size, position, and plating details. These files are essential for defining:

- Through-hole components and vias

- Blind and buried vias for multilayer PCBs

- Mounting holes and mechanical features

3. Bill of Materials (BOM)

The BOM lists all electronic components required for PCB assembly, including:

- Component part numbers

- Reference designators (R1, C2, U3, etc.)

- Quantity and supplier details

4. Pick-and-Place (Centroid) File

This file is essential for automated component placement and includes:

- X/Y coordinates for SMT parts

- Component rotation and polarity details

- Layer designation (top/bottom)

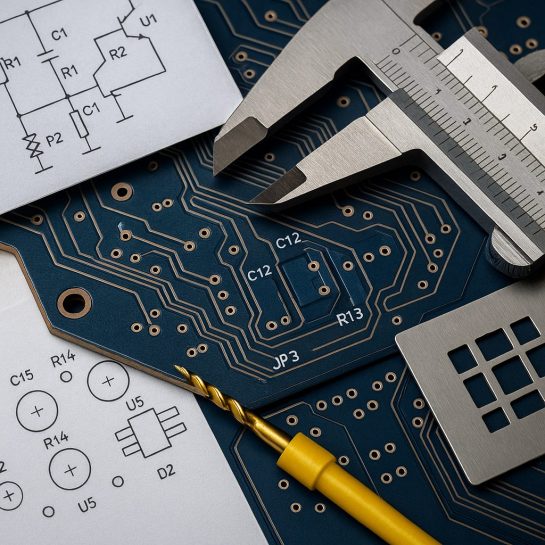

5. Assembly & Fabrication Drawings

To assist with PCB production and assembly, these drawings include:

- Board outline, cutouts, and mechanical dimensions

- Layer stack-up details

- Special instructions for assembly processes

6. Netlist File

The netlist verifies electrical connections between PCB components. This helps manufacturers check for missing or incorrect traces before production begins.

7. IPC-356 Test File (Optional)

- This file enables electrical continuity testing, ensuring all connections meet design specifications.

Having the correct files ensures accurate PCB fabrication, faster turnaround times, and reduced manufacturing errors. By preparing a complete file package, engineers can streamline the transition from design to production, ensuring high-quality PCBs.