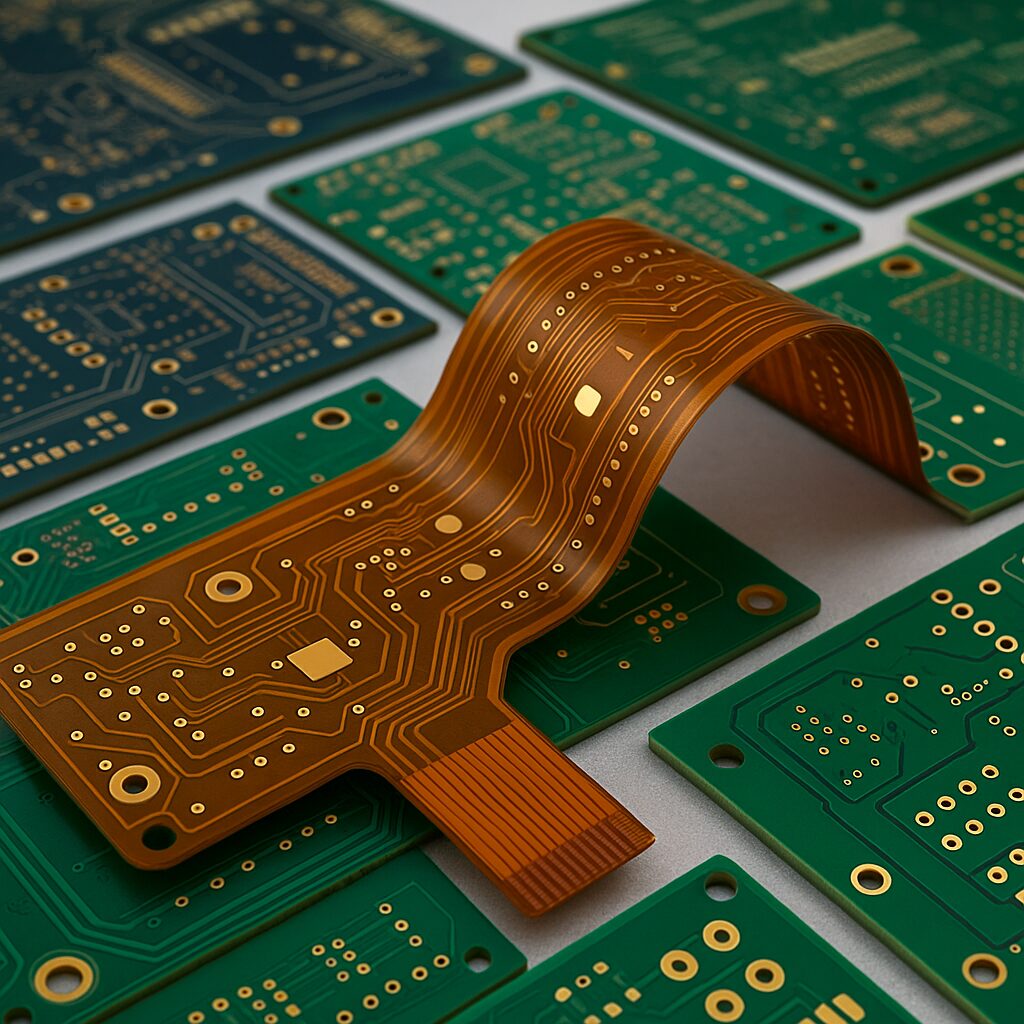

At Summit Interconnect, we view environmental responsibility not as a compliance checkbox but as a critical operational initiative. As a leading North American manufacturer of printed circuit boards (PCBs), we are committed to responsible manufacturing for high-reliability PCBs. From water conservation and energy efficiency to waste reduction and ethical sourcing, Summit is focused on sustainable electronics manufacturing in 4 main areas:

1. Water Reclamation

Water is an essential component of PCB fabrication, particularly during critical steps such as gold plating and chemical rinsing. Recognizing the environmental cost of high-volume water use, Summit has sophisticated water reclamation systems. For example, Summit Hollister facility uses an advanced ion exchange system designed to recover and recycle deionized (DI) water within a closed-loop process.

How It Works

During gold plating, rinse water becomes contaminated with trace metals like gold and nickel. Instead of sending this water through costly and wasteful treatment systems, ion exchange resin beds are used to filter and purify the water—removing these metals and returning clean DI water back into the production line.

At peak operation, this system can reclaim up to 25,000 gallons of water per day—significantly reducing both water consumption and wastewater output.

2. Automation

Water isn’t the only conservation initiative at Summit. Energy efficiency is another cornerstone of sustainability efforts, especially in high-consumption areas like chemical processing and plating lines.

The Problem with Traditional Lines

Conventional oxide and direct metallization (DM) lines often remain fully powered—even when idle—due to outdated equipment designs. This results in significant energy waste, excessive wear on mechanical systems, and higher maintenance demands. Instead, Summit’s upgraded automation systems intelligently shuts down heaters, pumps, and other energy-intensive components when not in active use. These systems also offer better temperature regulation and chemical dosing control, conserving energy.

Benefits

- Up to 50% reduction in idle energy consumption during non-peak hours.

- Decreased maintenance needs and extended equipment lifespan.

- Shorter production cycles and enhanced throughput.

- Lower carbon emissions as a result of optimized energy use.

Future plans include integrating real-time energy monitoring to further refine usage metrics.

3. Metal Recovery and Material Efficiency

PCB manufacturing is resource-intensive and can generate substantial volumes of metal shavings, excess plating materials, and worn-down tooling. At Summit, these byproducts don’t go to waste—they go back into production or are recycled responsibly.

Metal Reclamation

Unused copper, gold, tin, nickel, and other precious or base metals are collected, sorted, and recycled through trusted vendor programs. These materials are refined and reused, minimizing reliance on newly mined resources.

Drill Bit Resharpening

Drill bits are critical in multilayer PCB fabrication but degrade quickly. To reduce unnecessary waste, drill bits are resharpen for extended use. Depending on size, smaller bits can be reused once, while larger ones can be resharpened up to ten times—resulting in significant material savings and cost reductions.

Summit is also evaluating the use of Electro-Winning Cells—a technology that uses electrical current to recover metals like copper from wastewater.

4. Ethical & Sustainable Sourcing

Summit is committed to sourcing materials that are safe, sustainable, and responsibly produced—both environmentally and ethically.

Combatting “Forever Chemicals”

PFAS (per- and polyfluoroalkyl substances) are a class of synthetic chemicals found in many industrial products and linked to long-term environmental and health risks. Proactive steps have been taken to reduce and eliminate PFAS from Summit’s raw material sourcing by working with suppliers who comply with the latest environmental regulations.

Conflict-Free Commitment

Summit closely monitors the use of 3TG minerals (tin, tungsten, tantalum, and gold) to avoid contributing to conflict zones or unethical labor practices. In accordance with the Dodd-Frank Act, we partner with certified suppliers and participate in industry-wide transparency efforts to ensure ethical sourcing.

Material Innovation: Graphite Over Palladium

As a more environmentally friendly alternative to traditional palladium-based direct metallization, Summit has adopted graphite-based solutions. This shift avoids the environmental hazards associated with rare earth mineral extraction and hazardous chemicals like formaldehyde, creating a safer, greener process with less downstream waste.

The Road Ahead

Operational sustainability doesn’t stop at process improvements—it’s about creating a culture of continuous innovation that includes data-driven systems to track, analyze, and improve the company’s environmental impact.

Summit’s commitment to sustainability is about more than internal goals—it’s about providing value to customers. As more companies incorporate environmental, social, and governance (ESG) criteria into their supplier evaluations, transparent and results-driven practices help them meet their own sustainability benchmarks.

By combining smart manufacturing, transparent supply chains, and a culture of continuous improvement, Summit is laying the foundation for a more sustainable electronics industry—one board at a time.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing