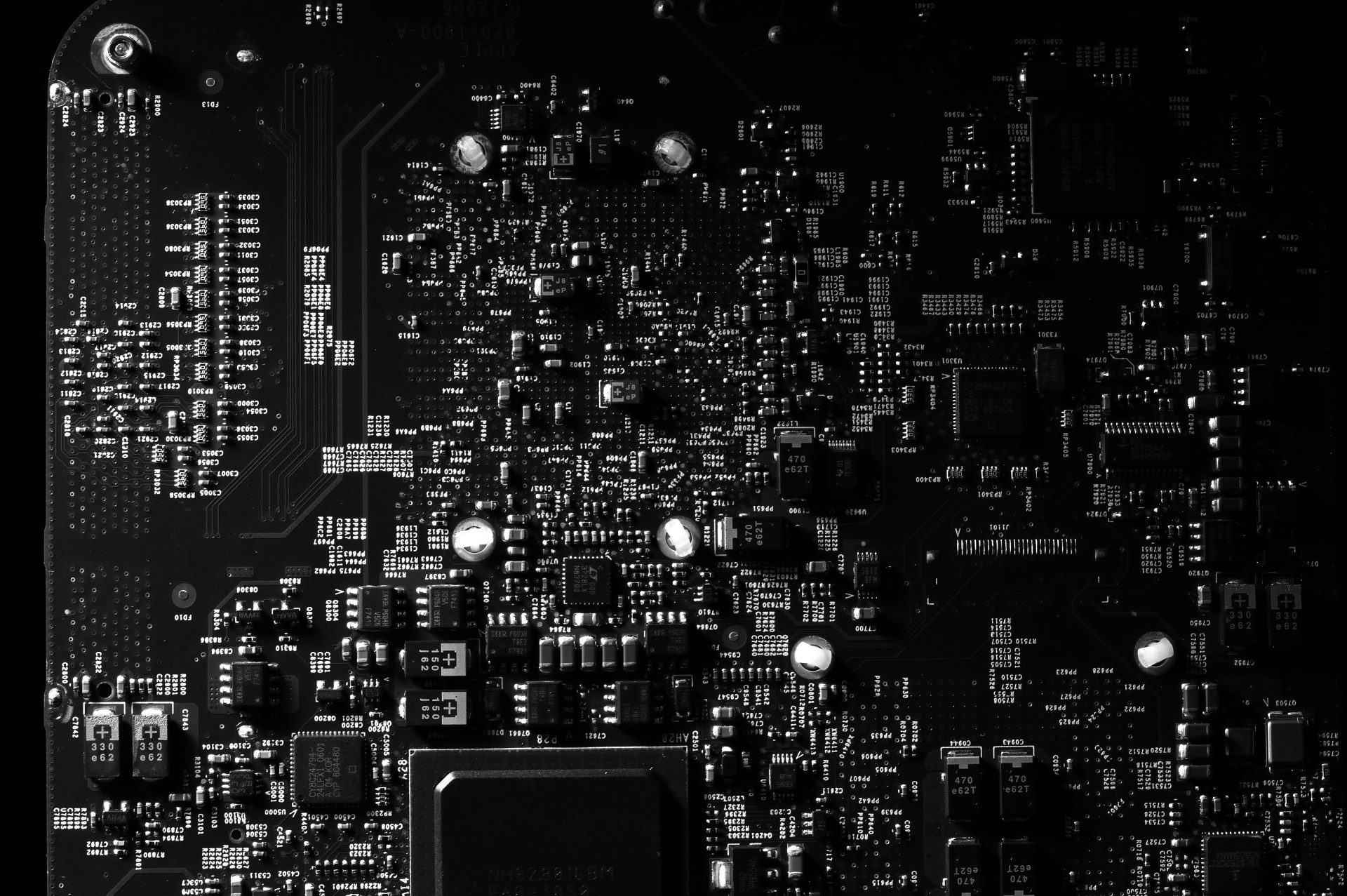

From advanced materials to new manufacturing techniques, the latest trends in PCB fabrication are changing the future of electronics. Here are some key trends in PCB fabrication technologies.

1. High-Density Interconnect (HDI) PCBs

HDI technology is becoming more prevalent due to its ability to support smaller, more compact designs. With microvias, laser drilling, and sequential lamination processes, HDI PCBs enable higher wiring densities, improving signal integrity and allowing for more complex circuit designs. Industries such as aerospace, medical devices, and telecommunications are increasingly adopting HDI technology for its enhanced performance and space efficiency.

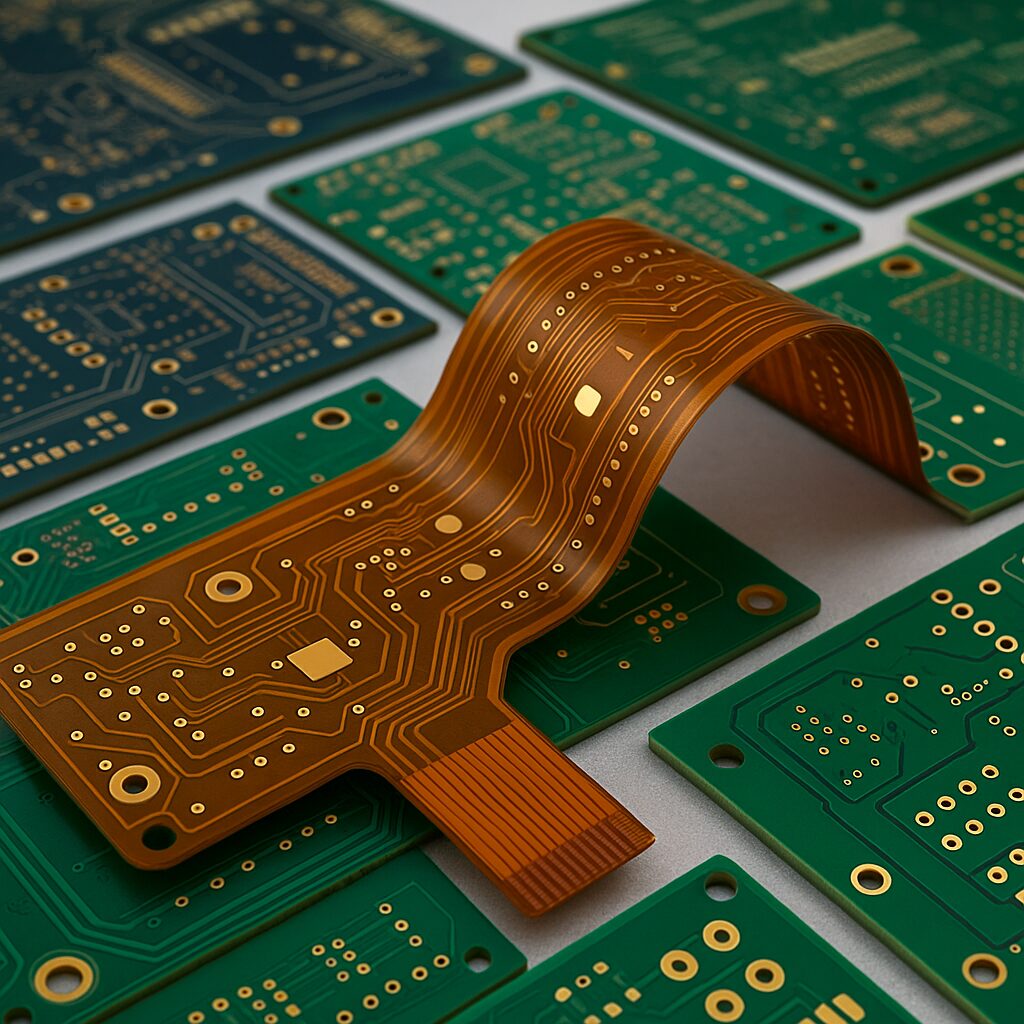

2. Flexible and Rigid-Flex PCBs

The demand for flexible and rigid-flex PCBs is growing, especially in applications requiring compact, lightweight, and durable solutions. These PCBs are commonly used in medical implants, wearable devices, and automotive electronics. Advancements in polyimide and liquid crystal polymer materials are improving the flexibility, heat resistance, and durability of these circuits.

3. Advanced Materials for High-Speed and High-Frequency Applications

With the rise of 5G technology and high-frequency applications, traditional FR-4 material is being replaced by advanced substrates such as PTFE-based laminates. These materials offer lower dielectric loss, improved thermal performance, and enhanced electrical properties, making them ideal for RF and microwave circuits.

4. Embedded Components and Embedded Cavity PCBs

Integrating passive and active components directly into the PCB structure is a growing trend, reducing board size and improving electrical performance. Embedded cavities allow for better thermal management and signal integrity, making them a preferred choice for high-power applications, such as power converters and automotive electronics.

5. Environmentally Friendly and Sustainable Manufacturing

Sustainability is a key focus in PCB fabrication, with manufacturers adopting greener practices such as lead-free soldering, reduced water consumption, and recycling initiatives.

6. Automation and Smart Manufacturing

Industry 4.0 and smart manufacturing are transforming PCB production with automated inspection systems, AI-driven design optimization, and real-time data analytics. Advanced robotics and machine learning algorithms are improving production efficiency, reducing defects, and enhancing overall quality control.

7. Increased Focus on Thermal Management

With electronic components generating more heat due to higher power densities, PCB manufacturers are developing advanced thermal management techniques. Innovations such as metal-core PCBs, embedded heat sinks, and thermally conductive dielectric materials help dissipate heat efficiently, improving device longevity and reliability.

8. Improved Surface Finishes for Enhanced Reliability

Surface finish technologies, such as electroless nickel immersion gold (ENIG), and immersion silver are improving PCB reliability and performance. These finishes provide reliable solderability, oxidation resistance, and enhanced electrical conductivity, making them essential for high-reliability applications.

Conclusion

As industries continue to demand smaller, faster, and more efficient electronics, PCB manufacturers are leveraging cutting-edge technologies to stay ahead of the curve. Whether through HDI designs, flexible materials, or smart manufacturing, the evolution of PCB fabrication is paving the way for the next generation of electronic devices.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing