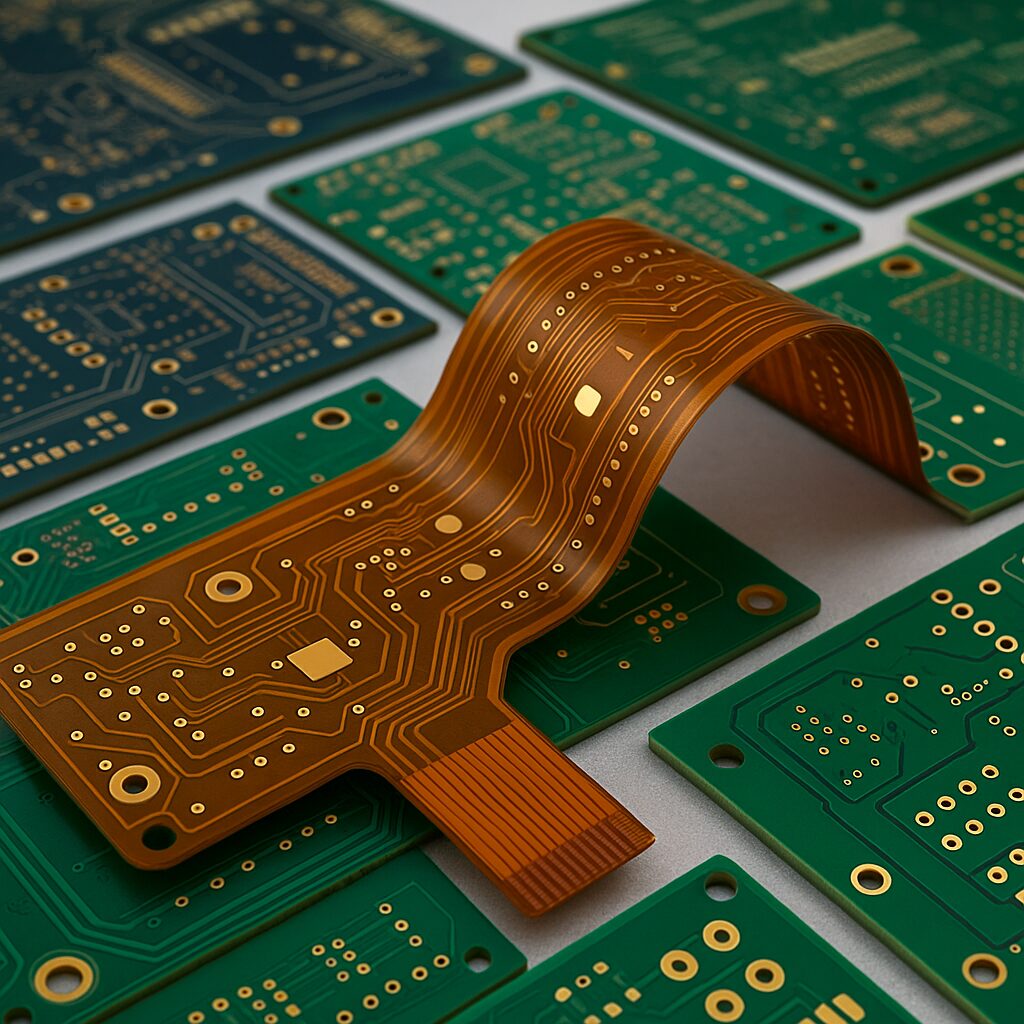

Kapton, a high-performance polyimide film, is widely used in PCB manufacturing due to its exceptional thermal, electrical, and mechanical properties. Developed by DuPont, Kapton is highly resistant to extreme temperatures, making it ideal for flexible circuits, aerospace electronics, and high-reliability applications.

Why Kapton is Essential for PCB Manufacturing

- Superior Thermal Resistance: Kapton maintains its stability across an extreme temperature range, from -269°C to +400°C. This ensures PCBs can withstand harsh environments without degradation.

- Flexibility and Durability: Kapton allows for bendable, lightweight, and compact circuit designs. It is commonly used in flex and rigid-flex PCBs, allowing designers to work within the space constraints of miniaturized electronics.

- Chemical & Electrical Stability: Kapton offers excellent resistance to chemicals, radiation, and electrical insulation breakdown, making it suitable for high-voltage circuits and medical devices where reliability is essential.

- Low Dielectric Constant (Dk) and Dissipation Factor (Df): Kapton exhibits very low Dk and Df values, making it an excellent material for high-frequency applications where signal integrity is crucial. When used in rigid PCBs, it enhances electrical performance by reducing signal loss and ensuring stable transmission at high speeds.

- High Mechanical Strength & Dimensional Stability: Kapton retains its structural integrity under mechanical stress, offering exceptional tear resistance and preventing warping or deformation, even in extreme environments.

Applications of Kapton in PCB Manufacturing

Flexible Printed Circuits (FPCs)

Kapton is the preferred substrate for flexible PCBs, allowing for dynamic bending and movement in applications like wearables, foldable displays, and medical implants.

Aerospace & Defense Electronics

Withstanding extreme space and military conditions, Kapton-based PCBs are used in satellites, avionics, and military communication systems.

High-Density Interconnect (HDI) & Miniaturized Designs

As electronic devices continue to shrink, Kapton supports ultra-thin PCBs while maintaining electrical performance for 5G networks, IoT devices, and microelectronics.

High-Frequency & RF Applications

Due to its low dielectric properties, Kapton is ideal for RF and microwave circuits where signal integrity is critical. It reduces signal attenuation, making it suitable for radar systems, telecommunications, and high-speed data transmission applications.

Conclusion

Kapton’s exceptional properties make it a cornerstone of modern PCB fabrication. Its ability to endure extreme conditions, provide flexibility, and ensure superior electrical reliability—including low dielectric losses—makes it indispensable in next-generation electronics and high-performance PCB designs.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing