Many Lean Managers look for companies that already have their own “Lean System” just to maintain the existing program. Only a handful can start from ground zero, which is the most challenging to implement.

Companies interested in encouraging regular improvement and development often adopt a lean culture. Fostering a lean culture can have many benefits for managers, teams, and organizations, including job satisfaction, productivity and quality products and services. To develop a lean culture, it’s important first to understand its elements and the strategies you can use to implement it. In this article, we explain what lean culture is, explore its benefits, list the steps you can take to develop it, and share the potential challenges of creating a lean culture and how to overcome them.

What is Lean Culture?

Lean culture is a type of company culture that focuses on continuous improvement, which refers to the optimization of an organization’s protocols and processes regularly. When the members of a company embrace this concept, they can develop a collective commitment to learning and improving that focuses on the needs and expectations of customers. Many companies encourage this type of culture when they plan to adopt lean business operations, which center on achieving optimal value while minimizing resource waste.

A lean culture emphasizes the roles that all employees play in this cycle of continually optimizing the efficiency of internal procedures. Employees at all levels and in all departments come together in a business with a lean culture to reduce organizational waste and create the best possible product for the customer. The four essential dimensions or pillars of lean culture are:

- Cultural enablers: Lean leaders are cultural enablers in that they encourage teamwork, respect each member of the team and promote cohesiveness within the organization.

- Continuous improvement: Organizations with a lean culture adopt the mindset of using scientific thinking to seek perfection in their processes and products.

- Enterprise alignment: Lean cultures have teams that work consistently and collaboratively toward shared objectives.

- Customer-focused results: Lean cultures prioritize creating results that bring the most value to the customer.

Why Have a Lean Culture?

Fostering a lean culture within an organization can have a range of benefits, including:

- Engagement with employees: Employees who understand how their individual contributions help their entire company may engage more with their jobs.

- Increased employee retention: Employees who feel engaged in their careers might be less likely to leave their job, which reduces turnover rates.

- Reduction of waste: Lean cultures focus on the primary goal of creating quality products and services while minimizing organizational waste, including money, time and material resources.

- Optimized collaboration: A lean culture emphasizes cooperation between various team members and departments, which can help organizations improve communication channels and collaboration efforts between a range of employees.

- Boosted revenue: Reduced organizational waste can help lead to higher revenue, which can lower costs and increase profit margins.

- Improved sustainability: Continually optimizing internal processes may help the organization improve its sustainability over an extended period.

How to Develop a Lean Culture?

Here are some steps you can take to develop and implement a lean culture:

- Consider the customer.

Before you focus on building a lean culture, consider the final product or service you want your customers to experience. One of the main tenets of the lean methodology is to provide customers with the optimal end-user experience. Consider their needs during all aspects of the business operations and encourage employees to do the same. Start by gathering regular feedback from customers when possible, such as through focus groups, surveys, product tests and online reviews. You might also evaluate metrics or key performance indicators (KPIs) related to your customers, like customer service response time or the content that your website visitors engage with most frequently. Then, you can collaborate with teams on how to meet these goals. - Develop expectations for behaviors.

It’s important for each member of the organization to understand the behavioral expectations that can facilitate a lean culture. Behavioral expectations refer to standards for how employees conduct themselves during various aspects of their job performance. These are an essential part of a lean culture because they ensure consistency and enable team members to complete their duties accordingly. You may decide to develop behavioral expectations based on the organization’s general operations or create different expectations for each department. For example, you might develop a specific set of behavioral expectations for customer service procedures and find that other guidelines are more applicable to production processes. Be sure to revise the company’s HR policies or systems as needed to align with these behavioral expectations. - Foster a learning environment.

Encourage employees to learn continuously and strive to optimize their personal performance. Creating an environment where company leaders help every employee learn new skills or advance their careers may encourage them to be proactive about improving individual and organizational processes. Strategies for fostering an environment of continuous learning and improvement include:- Developing internal training opportunities, such as courses or job shadowing positions

- Sending employees to industry conventions, workshops, or conferences

- Providing a way for employees to make suggestions about their department or the company to their supervisor.

- Collecting anonymous feedback from employees about various aspects of the organization at regular intervals

- Create a vision.

One way to create a clear purpose and establish a guiding principle in a lean culture is to establish an organizational vision. A company’s vision describes the plan for the company’s future based on its current goals. Develop a vision using the company’s mission and values as a framework and communicate it to employees throughout the organization. A specific company mission can help employees understand how to optimize company processes or protocols, realize the value of their specific contribution, and feel appreciated by the company. - Train all employees.

Regular training is critical to maintaining lean operations and fostering a lean company culture. Organizations with lean cultures typically apply lean operating principles, terminology, and strategies to the way members within the company interact with each other and perform their duties. Providing lean training sessions regularly to update employees and refresh their knowledge of lean principles can gain useful knowledge about the latest developments in lean methodology. This can promote efficiency within teams, which can lead to efficient. - Monitor performance metrics.

You can learn about how well your plan for implementing a lean culture is working by tracking and analyzing performance metrics for both teams and individuals. A critical aspect of continuous improvement is evaluating organizational data to determine how or where the company might reduce time, money, or other resources. This information can tell you whether teams are prioritizing lean methods when working as a team or independently on projects. The exact metrics you track depend on an array of factors, including the industry and the processes you want to optimize. They may include data related to quality assurance or control, customer service, deliverables, or safety protocols. Remember to share these metrics with teams to help them understand where they can learn and improve. - Create interdepartmental teams.

A key aspect of lean culture is using effective collaboration to create the highest potential value for the customer. While departments often work internally to perform their roles in the production process, companies can also benefit from allowing different teams to work together. This enables them to understand how their role in the process affects other teams and their responsibilities. Consider helping employees collaborate by designing interdepartmental teams to evaluate the efficiency of various processes within the company. Teams formed from a range of departments can bring together various perspectives into new collaborative efforts or ideas. This may also allow them to offer the company unique insights on how to reduce organizational waste and better meet the customer’s needs.

Potential Challenges of Developing a Lean Culture

Although creating a lean culture has many benefits, you may face certain challenges when you’re getting started. Here are a few common obstacles to developing a lean culture and how you might overcome them:

Lack of transparency

Many approaches to company operations involve specific levels of transparency, in which team members are only aware of certain aspects of a company’s processes and performance. Transparency is essential to lean culture, but leaders may find it challenging initially to have open communication with all members of the organization because of their prior management methods. You can overcome this by documenting important information and sharing it with team members during regular meetings.

Trial and error

While other operational methods focus on using the same techniques consistently, lean processes give teams an opportunity to look for improvements and change their procedures accordingly. This may feel unnatural to team members, as trial and error may seem inefficient. You can confront this challenge by encouraging teams to view every operational change as a learning experience and presenting data that details how the approach improves efficiency over a certain time frame.

Focus on output!

Companies often consider a high output more important than the value of the products or services they offer. As a learning culture, lean culture emphasizes the importance of creating the most value for the customer, which may affect the rate at which companies produce goods and services. If team members find this challenging, sharing customer feedback and explaining how the value-first approach can lead to a higher profit may help them overcome this mindset.

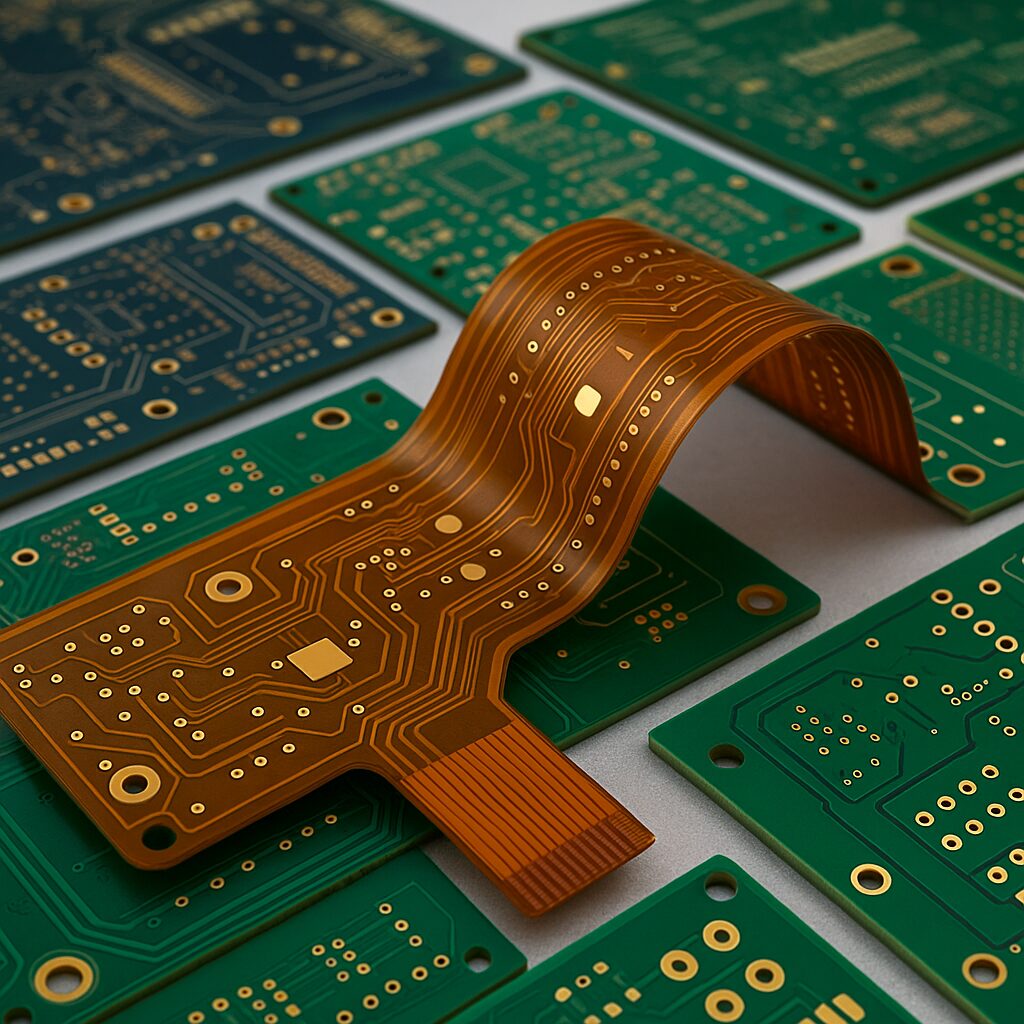

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing