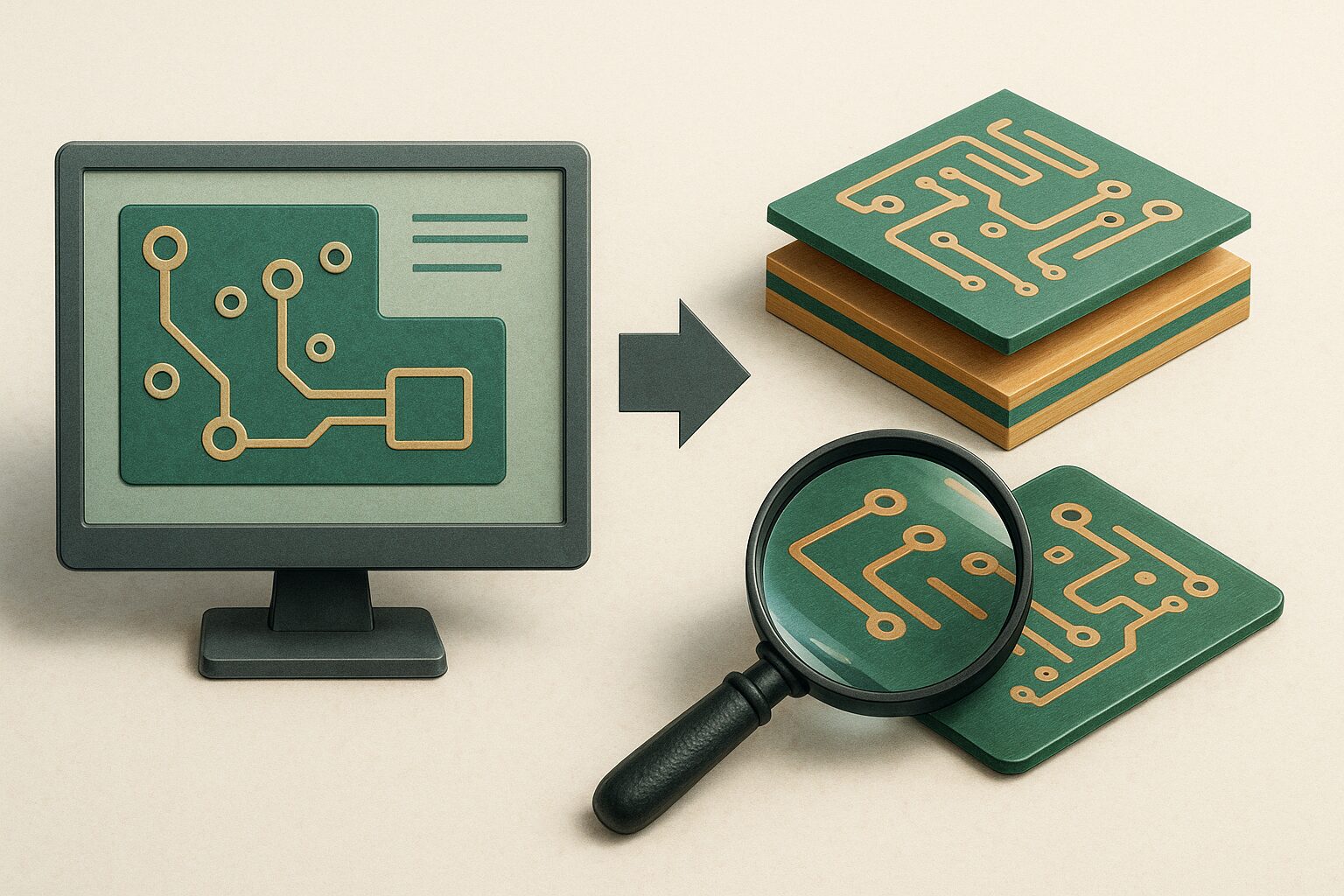

Before you layout a circuit, it’s generally a good idea to understand what is happening in your schematic. And before you lay out a schematic, it’s generally a good idea to understand what is happening in your block diagram.

Overview

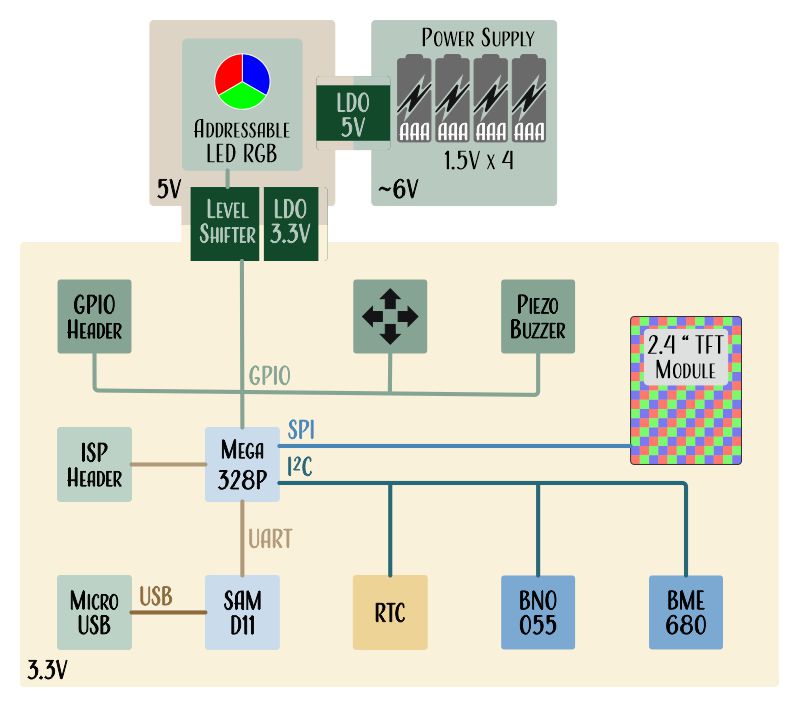

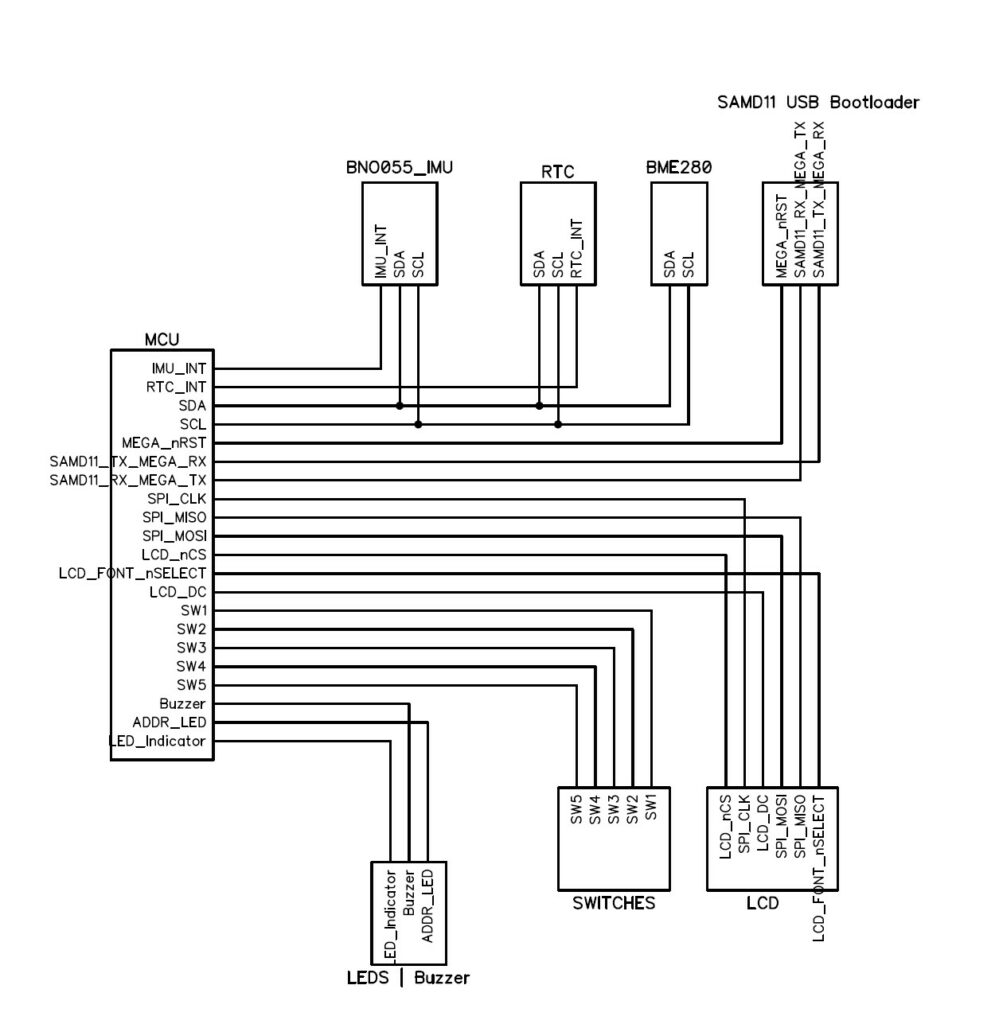

Below is the basic block diagram for a circuit. The job of an electrical engineer is to determine how to make each of the blocks and each of the data buses work correctly without interfering with any of the other parts of the circuit. Each block is converted to a schematic.

Power

The power in the circuit diagram above is delivered by batteries. The batteries feed a low-dropout (LDO) linear regulator that provides 5V to power the addressable RGB LEDs as well as a 3.3V LDO that powers the rest of the circuit. A logic-level translator will convert the Mega’s 3.3V logic outputs to 5.0V logic inputs.

Serial Data Bus

Four serial data buses are present in our circuit example and are used to transfer information.

- A Serial-Peripheral Interface (SPI) bus that communicates with the TFT module

- Universal Asynchronous Receive & Transmit (UART) that is used to program the microcontroller

- I2C that communicates with our sensors and Real-Time Clock (RTC) module

- A Universal Serial Bus that is used to communicate with an external computer for programming and debugging.

GPIO Pins

- Several pins will be used to command the Addressable RGB LEDs, read the status of push-buttons, and activate a piezo-buzzer.

Block Interaction

Blocks should be independently designed and connected to the main microcontroller. There are several common ways to do this such as with global nets and connector ports and hierarchical blocks. With hierarchical blocks, each circuit block is designed independently on a hierarchical page and then connected to the top-level via hierarchical connectors. In a hierarchical layout, only the connections between the blocks are shown on the top level (inputs, outputs, switch lines, etc…). Often times you’ll see power connections included as well.

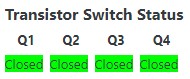

Power System Overview

Unless you are a fan of fire, it is not a good idea to use multiple power sources at once. Engineers cannot depend on users to remember to disconnect one source before they connect another. Passive or active measures must be used to prevent multiple sources from powering the circuit at the same time. The simplest option is to use a break-before-make selector switch. Adding a switch increases the BOM cost, and mechanical devices are prone to failure.

Let’s take a look at the four options available for power sources: Nothing attached, only battery power, only USB Power, and both usb and battery power.

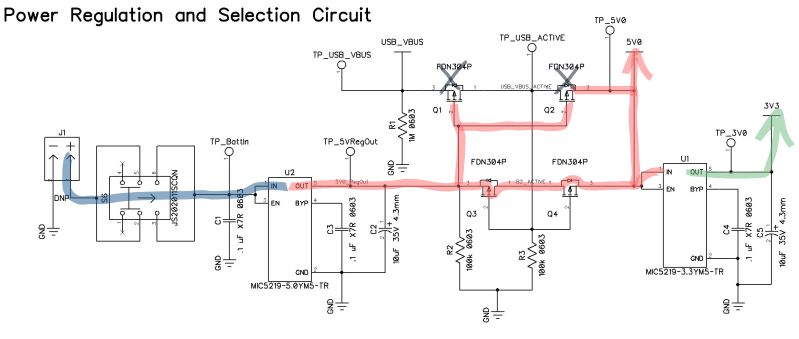

Option 1: Nothing Attached

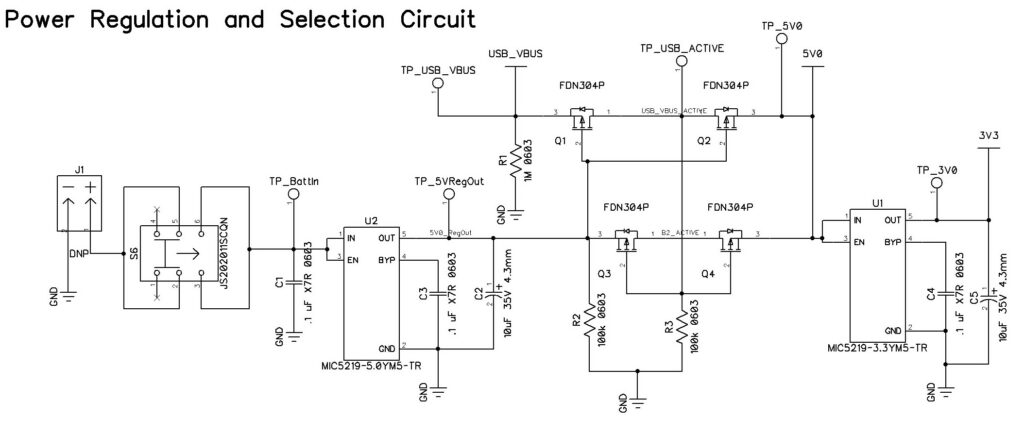

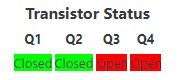

As you can imagine, nothing happens. P-channel MOSFETs behave as a normally closed (conducting) switch that opens (non-conducting) when a voltage is present at the gate. Since no voltage is present at the gate of Q1, Q2, Q3, or Q4, the “switches” are all closed and any current that arrives will be readily conducted.

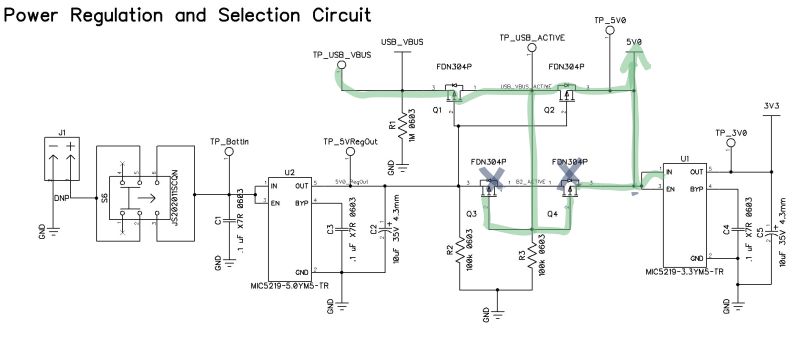

Option 2: Only Battery Attached

With the battery attached and the switch turned on, current flows through to the 5.0V LDO and through Q3 and Q4 to the 3.3V LDO and out to the rest of the circuit. R3 keeps the gate potential of Q3 and Q4 at 0V. At the same time, the gates of Q1 and Q2 are energized, stopping reverse conduction of current through the circuit.

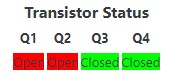

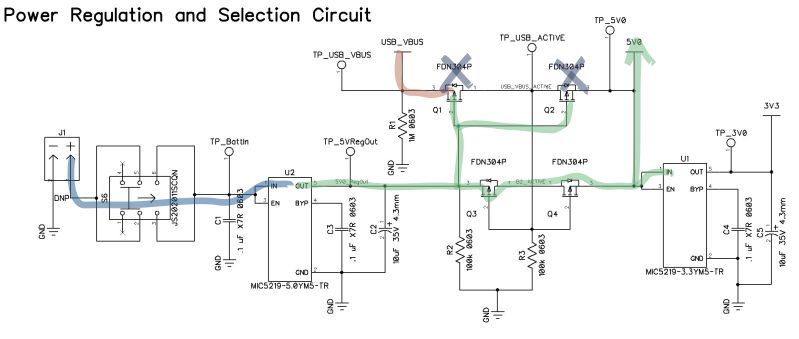

Option 3: Only USB Attached

With the USB power connected, R2 keeps the gate of Q1 and Q2 and ground potential, which keeps Q1 and Q2 conducting current between the source and drain. At the same time, the gates of Q3 and Q4 are connected to the net that connects Q1 and Q2, closing the conducting paths between Q3 and Q4 drain and source, which prevents the backward flow of current.

Option 4: Both Sources Attached

When both sources are energized, the 5.0 V LDO generates a potential difference at the gates of Q1 and Q2, shutting off the conduction path across the drain and source, stopping USB_VBUS current before it ever gets a chance to enter the rest of the circuit.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing