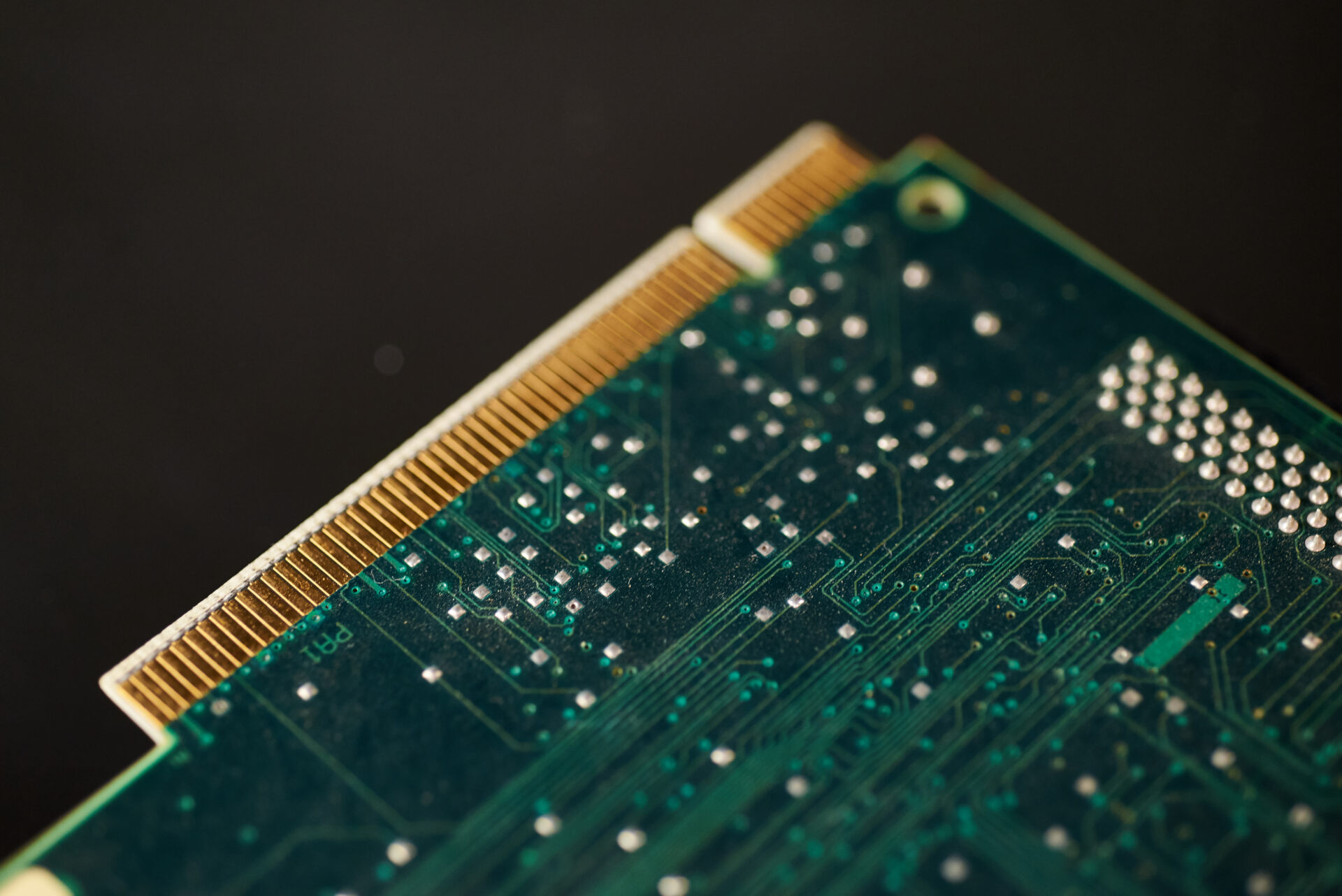

Quick-turn PCB prototypes are a timely solution for companies who require PCB models before the final manufacturing process. With the ability to produce a prototype within a specific timeframe, this option gives manufacturers time to analyze the product and make improvements before fabrication.

If these prototypes are something you require, here are four key factors to know about quick-turn PCB prototypes.

Save on Resources

Time, money, and energy are precious resources for any manufacturing facility, including those that fabricate printed circuit boards. Creating a prototype enables manufacturers to save on these resources during the printed circuit board fabrication process.

Time: Because PCB prototypes are created quickly by manufacturers who have extensive experience in the fabrication process, designers have more time to:

- Scrutinize and improve their PCB model before production.

- Focus on other business aspects that are demanding their attention.

Money: Since PCB prototypes are fabricated quickly, engineers have the ability to make critical changes before final fabrication, thereby reducing costs by saving on final PCB remakes.

Avoid Delays

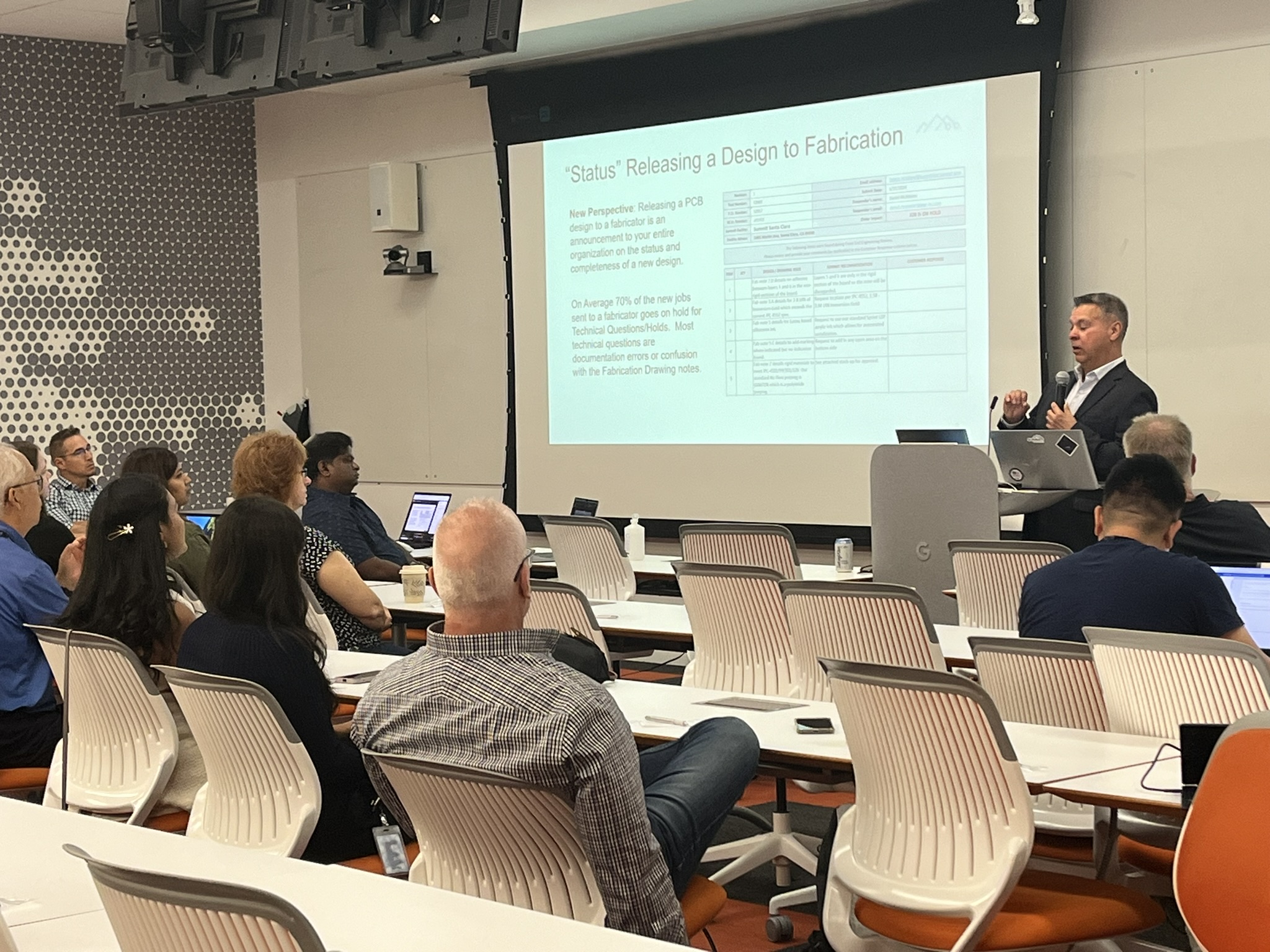

Quick-turn PCB models spare customers and manufacturers alike from delays in the production process. Additionally, customers don’t have to wait for the design to be verified or clarified.

Personal Service

Customers, manufacturers, engineers and technicians all work together to create the prototype before final production.

More Options

Options are an important aspect for companies to consider in a PCB. Established PCB production companies have everything needed to create a high-quality, custom product. These firms can meet unique needs related to production, tooling, shape, and size.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing