Companies across the nation are ramping up their production lines for ventilators but not all companies are qualified to perform the work. Only a fraction of the approximately 100 PCB manufacturing companies in the United States is capable of quickly fabricating and assembling the necessary circuit boards.

Summit Santa Ana, formerly Royal Circuit Solutions in Santa Fe Springs, California, is uniquely positioned to help out in the crisis. It’s production facility features the latest machinery, hardware, and production methods. The company has an inventory of copper-clad cores and prepreg, allowing it to start production as soon as the design files arrived from ventilator manufacturers.

Milan Shah, Vice President at Summit Interconnect, said “We have been producing circuit boards for ventilators for over 10 years. We have extended production hours and now have two shifts of engineers and production-line employees making the circuit boards that control ventilators. Our employees are putting in long hours, but we are so proud to be helping in this time of great need.”

Throughout the Covid-19 epidemic, as many as “960,000 Americans will require ventilatory support” (US Resource Availability for COVID-19, Society of Critical Care Medicine, March 2020.) A survey in 2009 identified approximately 160,000 ventilators in hospitals with another 12,700 in the Strategic National Stockpile (Worst -Case Estimates for US Coronovirus Deaths, New York Times, March 13, 2020). The large disparity between those two numbers means that potentially hundreds of thousands of Americans will not have the medical resources they need.

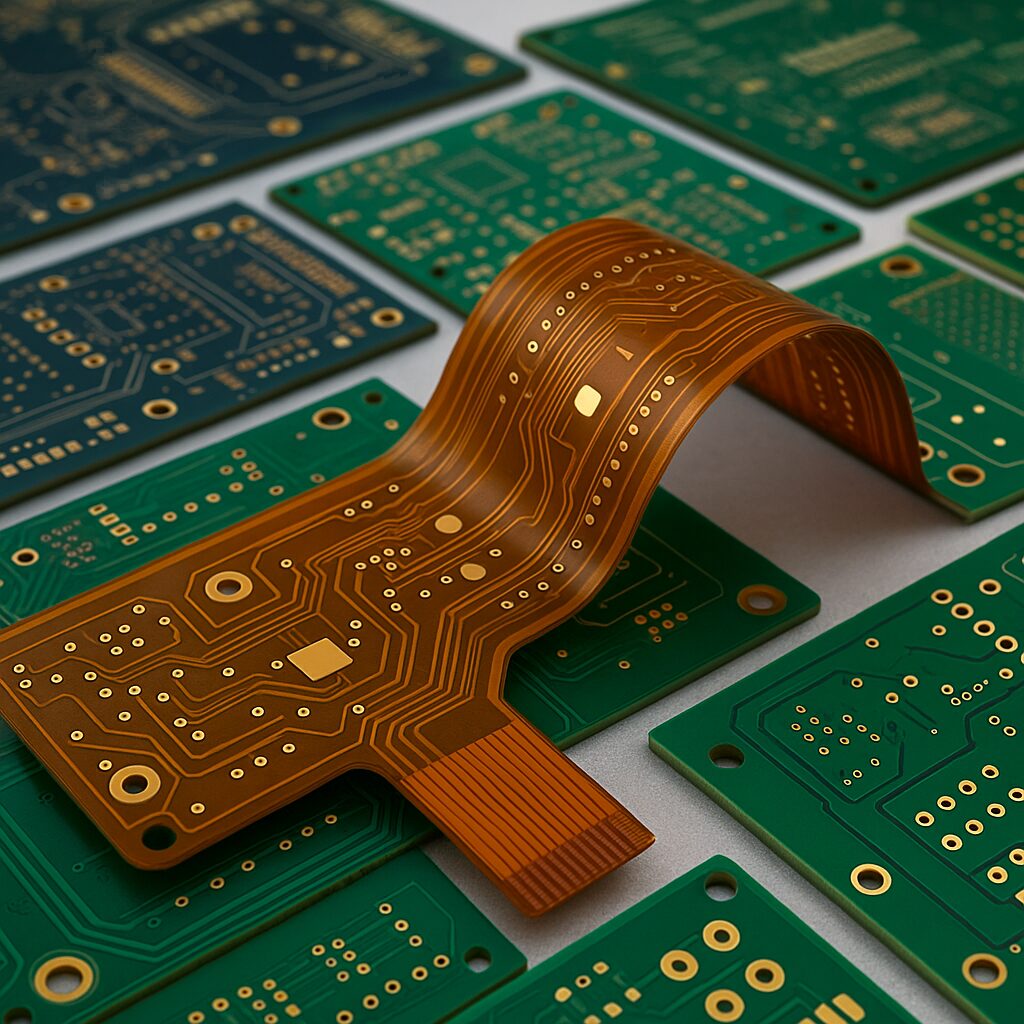

Summit manufacturers rigid, rigid-flex, and flexible printed circuits. “Fabricating and assembling flexible printed circuit boards is a very complex process that requires a fair amount of materials, a lot of labor and great attention to detail,” said Shah. “But done correctly, the net result is a product that helps saves lives.”

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing